Megawatt-Level (MW) Water-Cooled Virtual Load Cabinets

Megawatt-Level (MW) Water-Cooled Virtual Load Cabinets

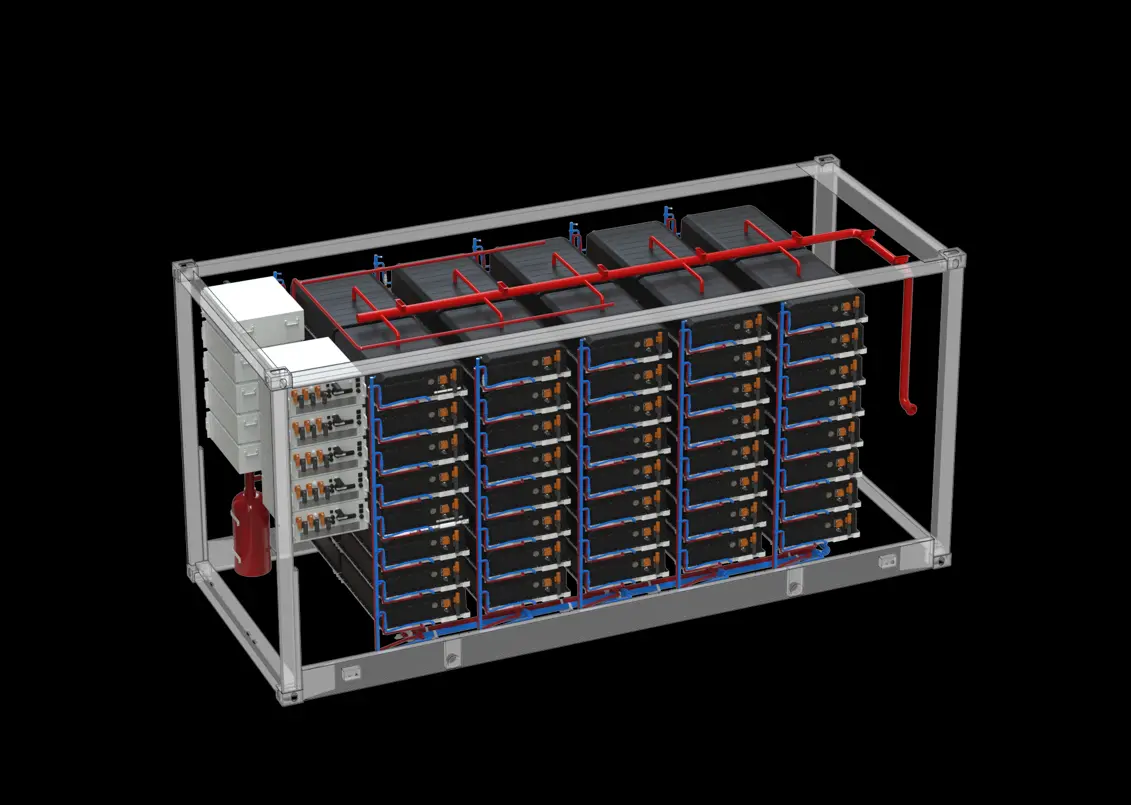

In today’s energy-driven world, ensuring the reliability and efficiency of power generation systems is critical. Megawatt-level (MW) water-cooled virtual load cabinets have emerged as indispensable tools for testing high-capacity generators, including diesel gensets, gas turbines, and renewable energy systems. These advanced testing solutions not only simulate real-world load conditions but also provide precise control over power dissipation and heat management. This article explores real-world applications of MW water-cooled virtual load cabinets, supported by actual data, to highlight their importance in generator testing.

What Are Megawatt-Level Water-Cooled Virtual Load Cabinets?

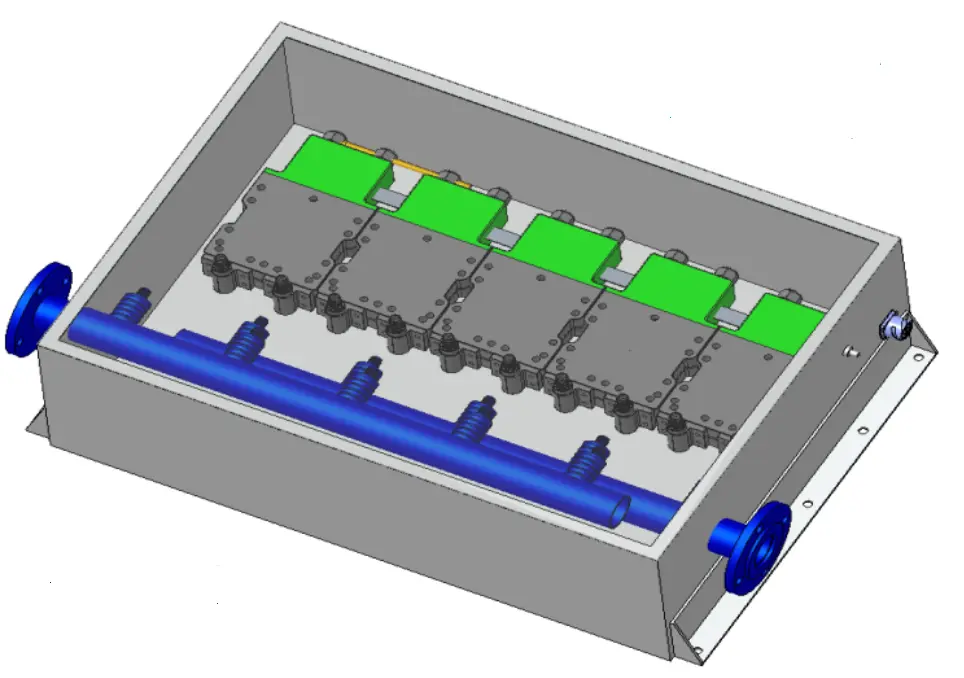

A megawatt-level water-cooled virtual load cabinet is a specialized device designed to absorb electrical power from generators and convert it into heat, which is efficiently dissipated through a water-cooling system. Unlike traditional air-cooled systems, water cooling offers superior thermal performance, making it ideal for high-power applications exceeding 1MW. These load cabinets are equipped with advanced control systems that allow operators to simulate various load profiles, including constant power, dynamic load changes, and overload conditions.

Key features of MW water-cooled virtual load cabinets include: High Power Density: Capable of handling loads up to several MW. Efficient Heat Dissipation: Closed-loop or open-loop water cooling ensures stable operation even during prolonged tests. Precision Control: Adjustable load settings and real-time monitoring for accurate performance evaluation. Low Noise Levels: Ideal for environments where noise pollution must be minimized.

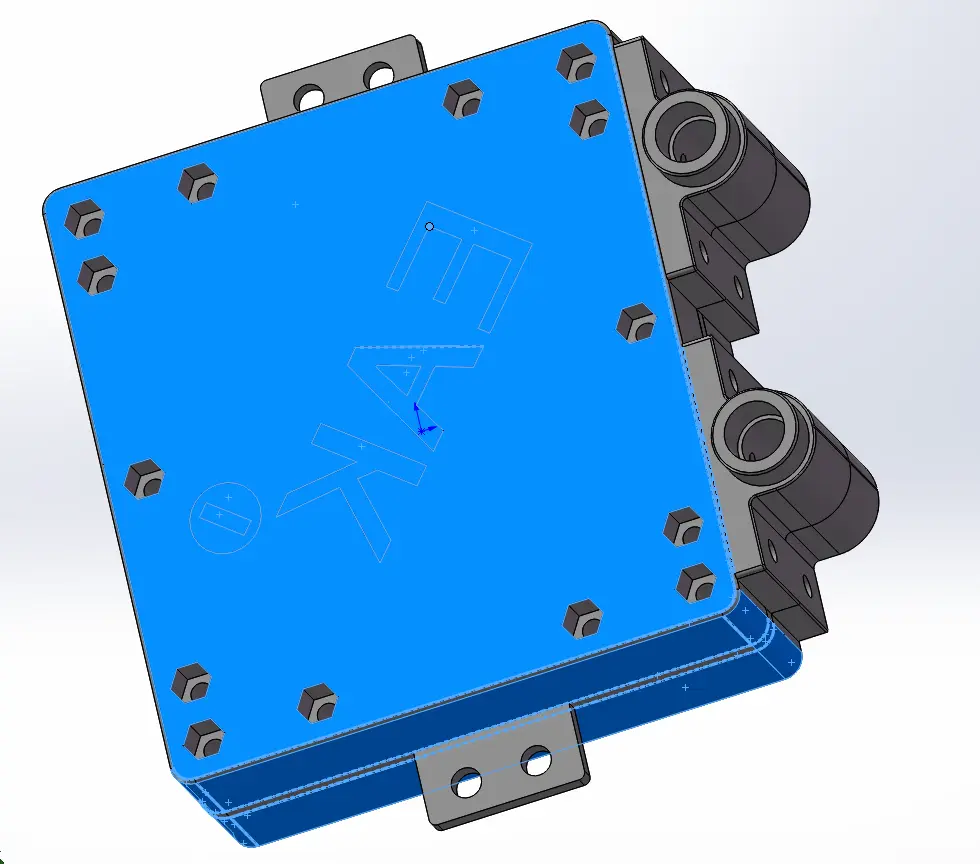

Water Cooled Resistors

Water Cooled Resistors

By incorporating these features, MW water-cooled virtual load cabinets have become essential for industries such as data centers, maritime operations, and renewable energy projects.

Case Study 1: Data Center Backup Generators

Background A leading cloud service provider installed three 2MW diesel generators at one of its hyperscale data centers to ensure uninterrupted power supply during grid failures. To validate the generators’ performance, the company conducted rigorous testing using MW water-cooled virtual load cabinets.

Testing Setup Load Cabinet Specifications: Three 2MW water-cooled virtual load units, each connected to a generator. Test Parameters: Full-load testing at 2MW per generator for 4 hours, followed by short-term overload testing at 2.2MW for 30 minutes. Cooling System: Closed-loop water cooling with an external chiller to maintain optimal operating temperatures.

Results Voltage Stability: Voltage fluctuations remained within ±1% during full-load operation. Frequency Stability: Frequency deviations were less than ±0.5Hz, ensuring consistent power quality. Thermal Performance: Cooling water temperature increased by only 8°C, demonstrating the effectiveness of the water-cooling system. Fuel Efficiency: The generators achieved a fuel consumption rate of 210g/kWh, aligning with manufacturer specifications.

| Parameter | Full Load (2MW) | Overload (2.2MW) | |————————|—————–|——————| | Voltage Fluctuation | ±1% | ±1.5% | | Frequency Deviation | ±0.5Hz | ±0.8Hz | | Runtime | 4 Hours | 30 Minutes | | Cooling Water Temp Rise| 8°C | 10°C |

This case underscores the importance of MW water-cooled virtual load cabinets in verifying the reliability of backup power systems.

Case Study 2: Maritime Genset Testing

Background A major port authority installed a 3MW marine generator to provide auxiliary power for docked vessels. Before commissioning, the generator underwent comprehensive testing using a single 3MW water-cooled virtual load cabinet.

Testing Setup Load Profile: Constant load at 3MW for 6 hours, followed by dynamic load cycling between 1MW and 3MW. Monitoring System: Integrated sensors tracked voltage, current, frequency, and coolant flow rates in real time. Cooling Method: Open-loop water cooling utilizing seawater from the port’s infrastructure.

Results Dynamic Response: The generator responded to load changes within 2 seconds without significant voltage or frequency drops. Operational Stability: Voltage and frequency deviations stayed below ±1% and ±0.5Hz, respectively. Thermal Management: Seawater cooling maintained a steady temperature rise of 7°C throughout the test duration.

| Parameter | Constant Load (3MW) | Dynamic Load (1MW–3MW) | |————————|———————|————————-| | Voltage Fluctuation | ±1% | ±1.2% | | Frequency Deviation | ±0.5Hz | ±0.8Hz | | Response Time | - | <2 Seconds | | Cooling Water Flow | 250L/min | 250L/min |

This application highlights how MW water-cooled virtual load cabinets support maritime power systems, ensuring compliance with international standards.

Why Choose MW Water-Cooled Virtual Load Cabinets?

1. Scalability: Available in modular designs, these cabinets can be scaled up to handle multi-MW loads. 2. Environmental Friendliness: Some models integrate heat recovery systems, allowing captured thermal energy to be reused for heating or industrial processes. 3. Durability: Built with robust materials, they withstand harsh operating conditions while maintaining long service life. 4. Cost Efficiency: By identifying potential issues early, these cabinets reduce maintenance costs and downtime.

Water Cooled Resistors

Water Cooled Resistors

Conclusion

Megawatt-level (MW) water-cooled virtual load cabinets play a pivotal role in ensuring the performance and reliability of high-capacity generators across diverse industries. From data center backups to maritime applications, these devices offer unparalleled precision, efficiency, and scalability. Backed by real-world data, they prove their value in delivering accurate, repeatable results under demanding conditions.

If you’re searching for state-of-the-art testing solutions for your power generation systems, consider investing in MW water-cooled virtual load cabinets. With their cutting-edge technology and proven track record, they represent the gold standard in generator testing equipment.