In high-power electrical systems where safety, reliability, and energy management are critical, the water-cooled discharge resistor built with carbon ceramic resistor technology stands out as a superior solution. Engineered for extreme conditions, this advanced resistor delivers unmatched performance in applications ranging from industrial braking systems to cutting-edge defense platforms.

Water-Cooled Discharge Resistor

Water-Cooled Discharge Resistor

Unmatched Energy Handling with Carbon Ceramic Resistor Technology

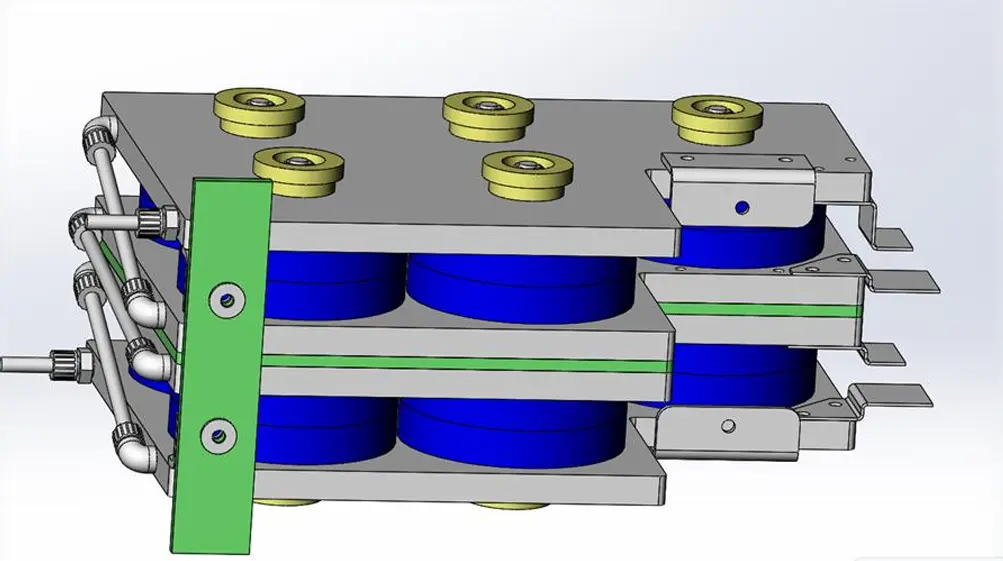

At the core of this system lies the carbon ceramic resistor—a robust, high-stability component known for its exceptional thermal conductivity, mechanical strength, and resistance to thermal shock. Unlike traditional wire-wound or metal oxide resistors, carbon ceramic resistors maintain stable resistance values even under repeated high-energy pulses, making them ideal for kJ to MJ (kilojoule to megajoule) level energy discharge scenarios.

These resistors are fabricated using a proprietary sintering process that bonds carbon and ceramic materials into a monolithic structure. The result is a non-inductive, flameproof, and corrosion-resistant element capable of withstanding harsh environments—whether in a factory floor, a naval vessel, or a high-altitude radar installation.

Efficient Thermal Management via Integrated Water Cooling

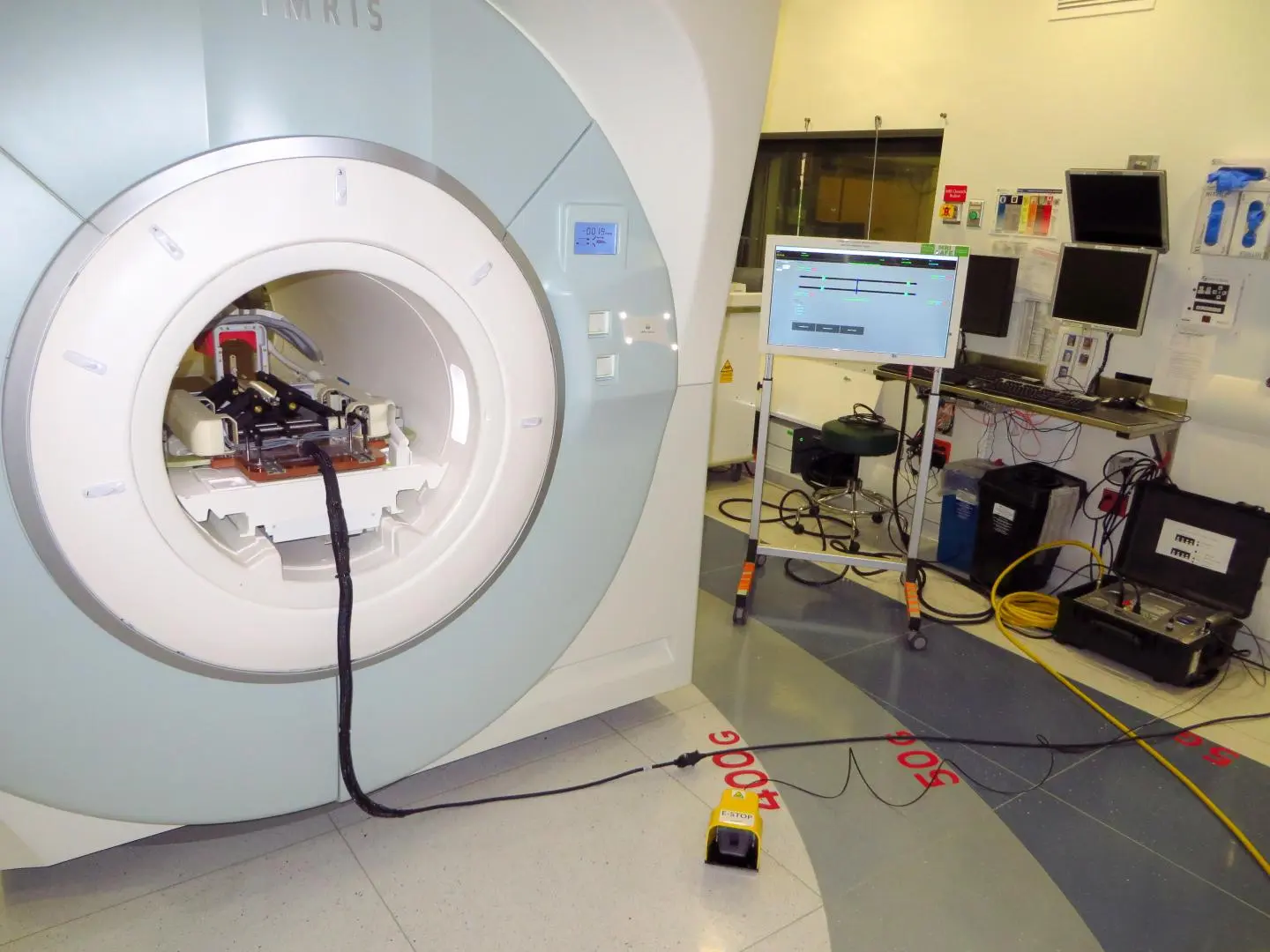

To handle the immense heat generated during rapid energy dissipation, our water-cooled discharge resistor integrates a closed-loop liquid cooling system directly into the resistor housing. This design enables continuous operation at high duty cycles without performance degradation. Compared to air-cooled alternatives, water cooling offers 5–10 times higher heat transfer efficiency, ensuring stable resistor temperature even under megajoule-level discharges.

The modular design supports flexible integration—multiple carbon ceramic resistor units can be arranged in series or parallel configurations to meet specific voltage, current, and energy requirements. This scalability makes the system adaptable for applications such as:

- Regenerative braking in heavy industrial machinery and electric vehicles

- Capacitor bank discharge in pulsed power systems

- Surge and fault current limiting in power grids

- Energy dump circuits in military radar, railguns, and directed-energy weapons

Proven Performance in Defense Applications

A flagship megajoule-class water-cooled discharge resistor developed with this technology has already entered mass production and deployment in a key national defense system. Independent evaluation by a panel of experts confirmed that its performance exceeds international benchmarks, achieving world-leading reliability and energy absorption capability. This validation underscores the resistor’s suitability for mission-critical applications where failure is not an option.

Carbon Ceramic Resistor

Carbon Ceramic Resistor

Modular, Compact, and Easy to Maintain

The product features a modular architecture with standardized mounting interfaces, allowing rapid installation and replacement. Units are housed in rugged enclosures with IP-rated protection, and all electrical connections are designed for low inductance and high current integrity. Optional forced-air cooling variants are also available for less extreme environments, offering design flexibility without compromising core performance.

Why Choose Our Water-Cooled Carbon Ceramic Discharge Resistor?

- Energy Rating: Scalable from kilojoules to megajoules

- Cooling Options: Primary water-cooling; optional forced-air

- Material Advantage: Non-inductive, flameproof carbon ceramic core

- Certified Reliability: Field-proven in defense systems

- Customizable: Series/parallel configurations for tailored impedance

For engineers designing next-generation power electronics, pulsed energy systems, or defense infrastructure, our water-cooled discharge resistor based on carbon ceramic resistor technology delivers the durability, efficiency, and performance required to meet tomorrow’s challenges—today.