The demagnetization device for large generator sets currently widely adopted is a magnetic field circuit breaker (with double or 3-4 multi-pole contacts) combined with nonlinear resistors (SiC or ZnO) for demagnetization technology. The key to achieving reliable energy transfer demagnetization is that the arc voltage of the magnetic field circuit breaker must be greater than the sum of the maximum voltage of the excitation power supply (under no-load over-excitation conditions) and the maximum residual voltage of the nonlinear resistor during demagnetization. However, the high arc voltage of the DC high-capacity magnetic field circuit breakers manufactured both domestically and internationally can no longer meet these requirements. The only temporary solution has been to lower the threshold voltage of the nonlinear resistors, sacrificing fast demagnetization time. Moreover, in practical use, issues such as synchronization due to multiple contacts have led to frequent incidents of contact wear and circuit breaker failures.

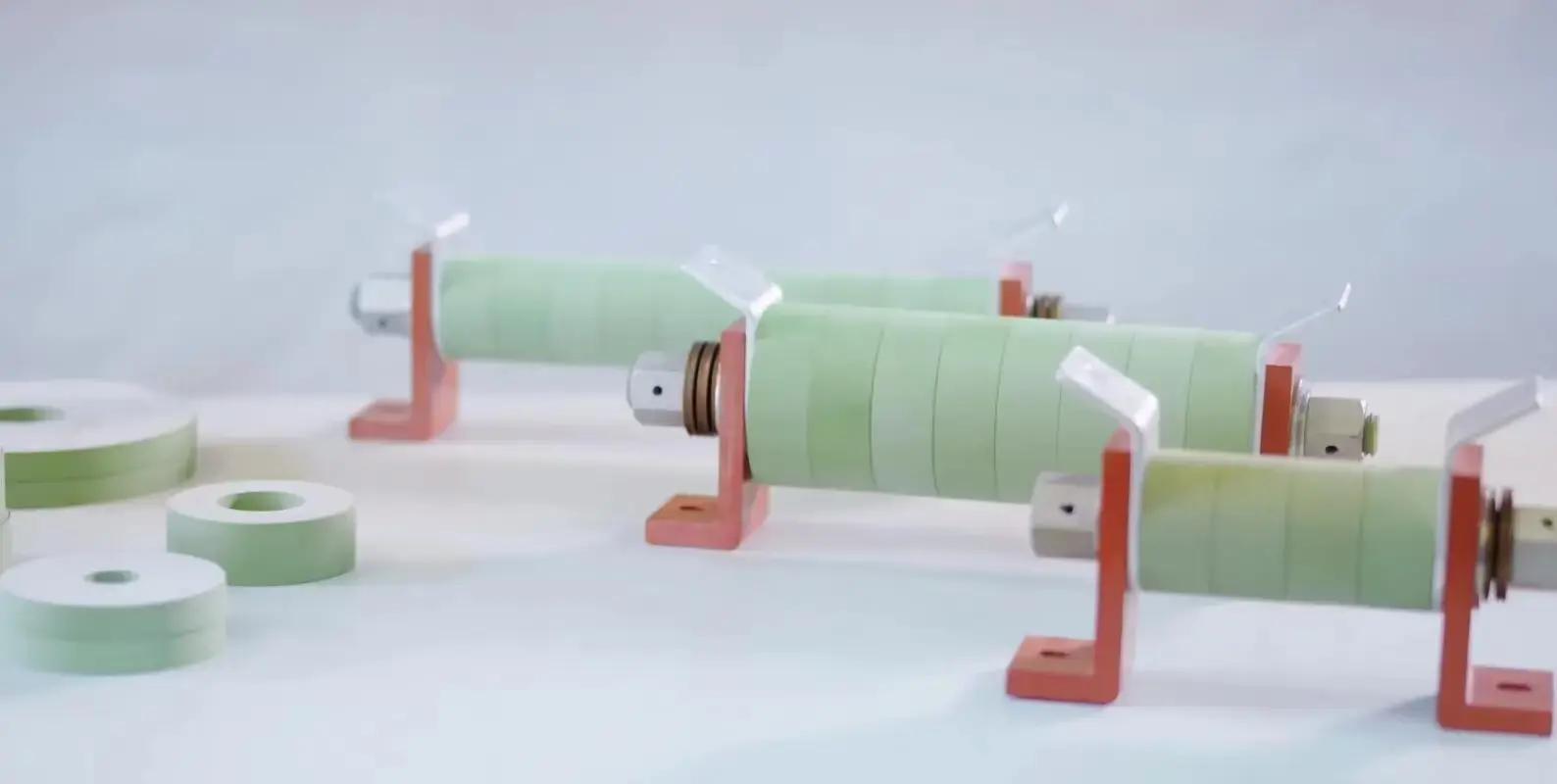

The combination of ZnO high-energy varistors and PTC thermistors into a new type of demagnetization device can effectively address two major challenges: the difficulty in establishing high arc voltage in the circuit breaker and the need to increase the threshold voltage of nonlinear resistors to meet fast demagnetization requirements. To this end, demagnetization tests were conducted using two methods in a laboratory with an adjustable large inductance (inductance of 1.96H, withstand voltage of 22kV, and current up to 30kA). One method involved using the DMX-800-2/1 switch combined with nonlinear resistors for demagnetization, and the other method used the GXW-2M switch combined with the new demagnetization device formed by ZnO high-energy varistors and PTC thermistors.