Inductors are fundamental components in electrical and electronic circuits, playing a critical role in energy storage, filtering, and signal processing. However, many engineers and enthusiasts are curious about where exactly an inductor stores its energy and why specialized equipment like liquid-cooled resistors is often required during the discharge process. In this article, we’ll explore these questions in detail while diving into the importance of liquid-cooled resistors in managing high-energy discharges effectively.

How Does an Inductor Store Energy?

An inductor stores energy within its magnetic field. When current flows through an inductor, it generates a magnetic field around the coil. This magnetic field is directly proportional to the amount of current passing through the inductor. The energy stored in the inductor can be calculated using the formula:

Where:

- E is the energy stored (in joules),

- L is the inductance of the inductor (in henries),

- I is the current flowing through the inductor (in amperes).

This means that the energy is not stored in the physical material of the inductor itself but rather in the magnetic field created by the flow of current. When the current stops or decreases, the collapsing magnetic field induces a voltage across the inductor, which can lead to significant energy release.

The Discharge Process: Challenges and Solutions

When an inductor discharges, the stored energy must be dissipated safely. If not managed properly, this energy can cause voltage spikes, overheating, or even damage to surrounding components. This is particularly problematic in high-power applications such as industrial machinery, renewable energy systems, and electric vehicles, where inductors handle large currents.

Why Use Liquid-Cooled Resistors for Inductor Discharge?

Liquid-cooled resistors are specifically designed to handle high levels of energy dissipation efficiently. Here’s why they are commonly used in the discharge process:

- High Power Handling Capacity

- Liquid-cooled resistors can dissipate significantly more power than their air-cooled counterparts. This makes them ideal for applications involving large inductors that store substantial amounts of energy.

- Effective Heat Dissipation

- During the discharge process, resistors convert electrical energy into heat. Without proper cooling, excessive heat buildup can degrade performance or cause failures. Liquid cooling provides superior thermal management by circulating coolant (such as water or oil) around the resistor elements, ensuring consistent temperature control.

- Compact Design

- Compared to traditional air-cooled resistors, liquid-cooled versions offer a smaller footprint while maintaining high efficiency. This is crucial in space-constrained environments like data centers, electric vehicles, and aerospace systems.

- Durability and Reliability

- Liquid-cooled resistors are built to withstand harsh operating conditions, including high temperatures and frequent cycling. Their robust design ensures long-term reliability, reducing maintenance costs and downtime.

- Noise Reduction

- Unlike fans used in air-cooled systems, liquid-cooled resistors operate silently. This is especially beneficial in noise-sensitive environments such as hospitals, laboratories, and residential areas.

Applications Requiring Liquid-Cooled Resistors

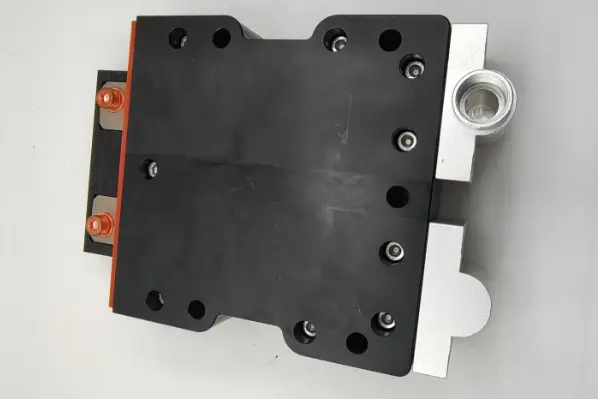

liquid-cooled resistors

liquid-cooled resistors

The use of liquid-cooled resistors extends beyond just inductor discharge processes. They are widely employed in various industries due to their ability to manage high-energy loads safely and efficiently. Some notable applications include:

- Renewable Energy Systems : Wind turbines and solar inverters rely on liquid-cooled resistors to dissipate excess energy generated during sudden changes in wind speed or sunlight intensity.

- Electric Vehicles (EVs) : EV charging stations and regenerative braking systems utilize liquid-cooled resistors to handle rapid energy transfers without overheating.

- Industrial Machinery : Large motors and transformers require liquid-cooled resistors to absorb transient energy surges during startup or shutdown sequences.

- Railway Systems : Trains equipped with dynamic braking systems depend on liquid-cooled resistors to safely dissipate kinetic energy converted into electrical form.