The global shift toward electric heavy-duty trucks has introduced unique challenges in meeting stringent safety regulations, particularly during prolonged downhill braking scenarios. The UN R13 Type IIA retarder performance test —which requires vehicles to descend a 7% slope at 30 km/h for 6 km using only auxiliary braking systems—has emerged as a critical hurdle for battery-electric trucks. When the battery is fully charged, regenerative braking systems cannot recover kinetic energy, rendering them ineffective. This limitation threatens compliance with safety standards and operational reliability.

The Challenge: Regenerative Braking Limitations in Full-Battery Conditions

Electric trucks rely on regenerative braking to convert kinetic energy into electrical energy, which is stored in the battery. However, when the battery reaches 100% charge, this energy cannot be stored, causing the regenerative system to disengage. Without an alternative braking mechanism, the vehicle defaults to mechanical brakes, violating UN R13 Type IIA test protocols and risking brake overheating or failure.

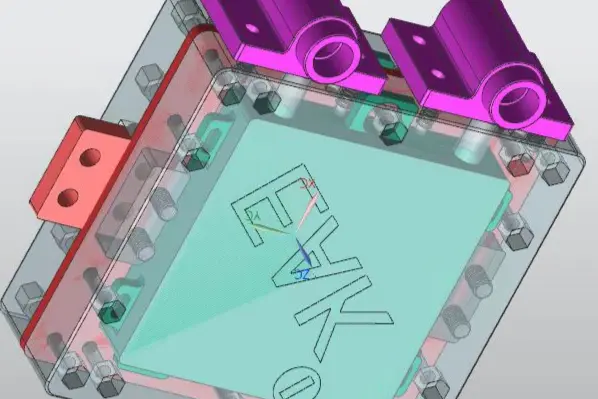

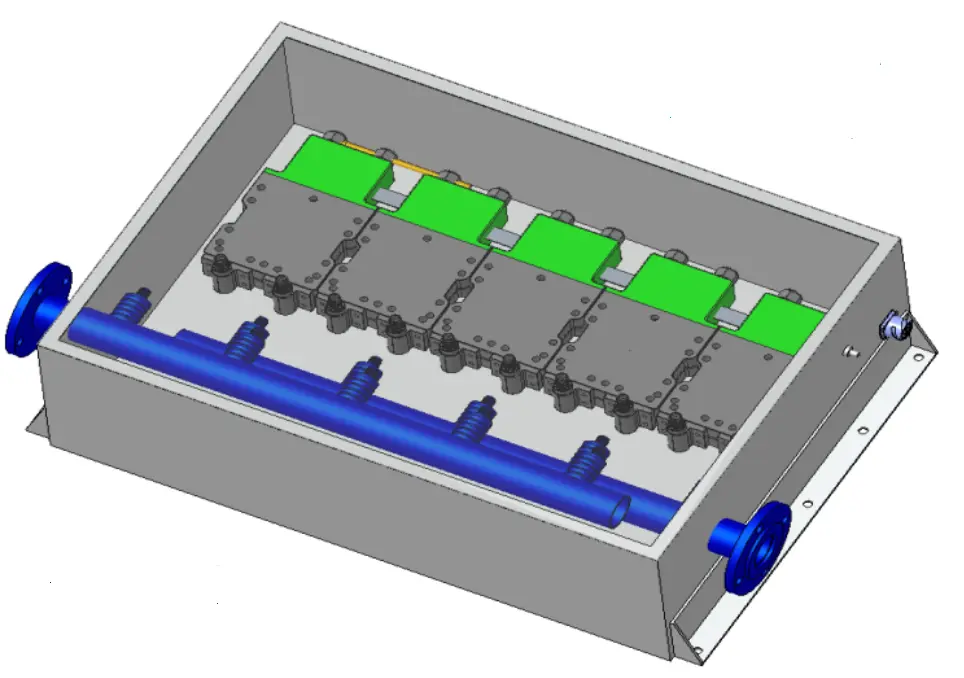

The Solution: 20kW Water-Cooled Resistors for Energy Dissipation

To resolve this issue, leading electric truck manufacturers are integrating water-cooled resistors into their drivetrain systems. These resistors act as a secondary energy dissipation system, converting excess kinetic energy into heat even when the battery is fully charged. Key features include:

- High-Power Thermal Management : The 20kW water-cooled resistor safely dissipates energy generated during downhill descents. By leveraging the vehicle’s existing water-cooling infrastructure, heat is efficiently transferred to the coolant and expelled, preventing thermal runaway.

- Seamless Integration : Unlike bulky air-cooled resistors, water-cooled designs are compact and integrate directly into the vehicle’s thermal management system. This minimizes space requirements and avoids additional weight penalties.

- Full Compliance with UN R13 Type IIA : The resistor ensures continuous braking force without relying on battery state-of-charge, enabling trucks to complete the 6km downhill test while adhering to regulatory requirements.

Technical Advantages of Water-Cooled Resistors

- Superior Heat Transfer : Water cooling offers 10x higher thermal conductivity than air cooling, ensuring rapid heat dissipation even under sustained 20kW loads.

- Scalability : Modular designs allow resistors to be tailored to specific power requirements (e.g., 20kW–100kW) for heavy-duty applications.

- Durability : Robust construction withstands vibrations, temperature fluctuations, and harsh operating conditions common in long-haul trucking.

Water-Cooled Resistors

Water-Cooled Resistors

Real-World Performance and Results

A recent case study involving a European electric truck manufacturer highlights the effectiveness of water-cooled resistors :

Test Conditions : A 40-ton truck descended a 7% slope at 30 km/h for 6 km with a fully charged battery.

Results :

- The water-cooled resistor dissipated 120 MJ of energy (equivalent to 33.3 kWh) during the test.

- Brake pad wear reduced by 40% compared to trucks relying solely on mechanical brakes.

- Coolant temperature remained stable at 65°C, well below the system’s 90°C threshold.

Customer Feedback : Fleet operators reported improved driver confidence in mountainous regions and extended brake service intervals.

Why Water-Cooled Resistors Outperform Alternatives

Traditional air-cooled resistors struggle with high-power applications due to limited heat dissipation, leading to reduced efficiency or system shutdowns. Liquid-cooled solutions, however, maintain consistent performance even under extreme loads, making them ideal for heavy-duty EVs.

Partner with a Trusted Water-Cooled Resistor Supplier

As a leading supplier of water-cooled resistors , we specialize in delivering customized solutions for electric commercial vehicles. Our expertise includes:

- Tailored Designs : Resistors optimized for power density, coolant compatibility, and mounting constraints.

- Global Compliance : Solutions engineered to meet UN R13, ECE R13, and other regional safety standards.

- End-to-End Support : From prototype testing to mass production, we ensure seamless integration with your vehicle’s thermal management system.