As the world accelerates toward electrification, renewable energy integration, and high-performance power systems, traditional passive components are evolving into intelligent, active participants in energy management. Among them, the intelligent liquid-cooled resistor is emerging as a critical node in next-generation power control—especially when enhanced with advanced thermal materials like synthetic diamond.

Gone are the days when braking or dump resistors were simply “burn off” excess energy with little control or insight. Today’s intelligent liquid-cooled resistors integrate sensors, embedded controllers, and communication interfaces to become smart energy regulation units that actively participate in system stability, safety, and efficiency.

From Passive to Intelligent: The Evolution of Resistors

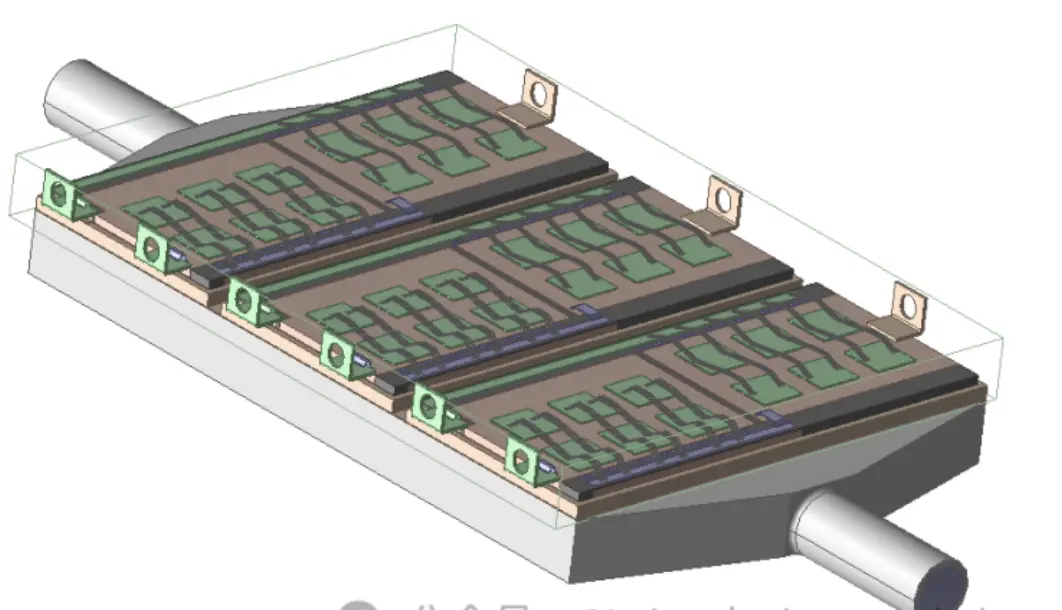

Modern intelligent liquid-cooled resistors are equipped with real-time monitoring capabilities:

- Built-in temperature, flow, pressure, and voltage/current sensors

- Embedded MCUs for local decision-making

- Support for industrial protocols like Modbus, CANopen, and EtherCAT

This enables them to autonomously respond to system conditions—engaging when DC bus voltage rises, disengaging when energy can be regenerated, and reporting health status to SCADA or cloud platforms. In electric vehicles, trains, wind turbines, and data centers, they no longer just dissipate heat—they manage energy flow intelligently.

Diamond-Enhanced Thermal Performance

One of the biggest challenges in high-power resistors is thermal density. Even with liquid cooling, hotspots can degrade performance and shorten lifespan. This is where synthetic diamond comes in.

Diamond has the highest thermal conductivity of any known material—up to 2,000 W/m·K, five times that of copper. By integrating diamond-based heat spreaders or coating resistor substrates with diamond-like carbon (DLC), heat is rapidly extracted from the resistive element and transferred into the coolant.

When combined with microchannel liquid cooling, diamond-enhanced resistors achieve:

- Ultra-fast heat dissipation

- Reduced thermal resistance

- Higher power density in smaller footprints

- Extended operational life under continuous load

This makes them ideal for space-constrained, high-reliability applications like aerospace, EV powertrains, and compact energy storage systems.

Applications Driving the Future

- Electric & Hybrid Vehicles: During regenerative braking, intelligent resistors absorb excess energy when batteries are full. Diamond cooling ensures sustained performance without thermal throttling.

- Wind Turbines & Solar Farms: During grid faults, these resistors prevent overvoltage by dumping surplus power. With diamond-enhanced cooling, they support longer low-voltage ride-through (LVRT) events.

- Rail & Metro Systems: Onboard intelligent liquid-cooled resistors manage dynamic braking energy. Integrated with train control networks, they optimize energy use and reduce maintenance.

- Industrial Test Benches: As programmable electronic loads, they simulate real-world conditions. Diamond cooling enables 24/7 full-power testing with minimal downtime.

- Data Center UPS Systems: In mission-critical power backup, they protect inverters from overvoltage. Their silent, efficient operation aligns with green data center goals.

Toward a Smarter Energy Ecosystem

The future of intelligent liquid-cooled resistors lies in system-level integration. Imagine a resistor that:

- Predicts its own failure using AI-driven analytics

- Communicates with battery management systems (BMS) to prioritize energy recovery

- Participates in microgrid load balancing as a “virtual load”

- Joins a digital twin platform for real-time performance modeling

With diamond-based thermal management, these capabilities become not just possible—but reliable and scalable.

Conclusion

The intelligent liquid-cooled resistor is no longer just a component; it’s a smart energy gatekeeper. When empowered with real-time control, communication, and diamond-enhanced cooling, it becomes a cornerstone of efficient, resilient, and sustainable power systems. As demands for power density and reliability grow, the fusion of intelligence + liquid cooling + diamond thermal technology will define the next generation of energy management—where every watt is not just used, but wisely managed.