In the rapidly evolving landscape of high-voltage direct current (HVDC) systems, power efficiency and reliability are paramount—especially as AI data centers push boundaries with 800V architectures supporting over 1MW per rack. Enter the Snubber liquid-cooled resistor, a game-changing component that’s redefining how we manage transient energy spikes and harness regenerative power. If you’re an engineer, data center operator, or sustainability advocate, understanding the Snubber liquid-cooled resistor could be your key to optimizing HVDC performance. In this post, we’ll dive deep into its pivotal role as a braking resistor and in energy recovery, backed by real-world insights from cutting-edge deployments.

What is a Snubber Liquid-Cooled Resistor?

At its core, a Snubber liquid-cooled resistor is an advanced RC (resistor-capacitor) snubber circuit designed for high-power environments. Traditional snubbers protect power semiconductors like SiC MOSFETs from voltage overshoots during switching, but the liquid-cooled variant takes it further with integrated fluid cooling—think water or specialized dielectrics circulating through cold plates to dissipate heat rapidly.

Why liquid cooling? In HVDC systems, where currents can surge to 900A and voltages hit 800V, air-cooled resistors simply can’t keep up. Liquid cooling boosts power density by 2-3x, shrinks footprints by 40%, and maintains temperatures below 200°C even under sustained kW-level loads. SiC-based models, leveraging silicon carbide’s superior thermal conductivity, are particularly suited for these demands, offering breakdown voltages >800V and energy dissipation rates up to 10kW per module.This isn’t just incremental tech—it’s essential for the next-gen HVDC grids powering AI factories and renewable energy hubs.

The Braking Function: Taming Transients in HVDC

One of the standout applications of the Snubber liquid-cooled resistor in HVDC systems is as a braking resistor. In dynamic loads—like GPU clusters in NVIDIA’s Rubin platform suddenly ramping down—excess energy can cause voltage spikes (dv/dt) that fry components. Here, the snubber acts as a dynamic brake, absorbing and dissipating this surge energy as heat.

- How it works: Paired with a capacitor, the resistor forms a damping network that limits peak currents and voltages. In an 800V HVDC setup, it can handle transient spikes of several kJ in milliseconds, preventing overshoots that could exceed 1.5x nominal voltage.

- Real-world impact: In AI data centers transitioning to 100kW+ racks, uncontrolled braking leads to 15-20% efficiency losses. A Snubber liquid-cooled resistor mitigates this, stabilizing SiC/GaN converters and extending module life by 50%. Delta Electronics’ 800VDC solutions, for instance, integrate these for seamless 1.1MW rack operation, reducing downtime in high-stakes training runs.

By converting harmful transients into manageable heat, these resistors ensure HVDC systems run cooler, quieter, and more reliably—crucial for 24/7 operations.

Energy Recovery: Turning Waste into Power

Beyond braking, the Snubber liquid-cooled resistor shines in energy recovery, transforming dissipated heat back into usable power or minimizing waste in regenerative HVDC loops. Traditional resistors just burn energy as heat; liquid-cooled snubbers, however, enable bidirectional flow, feeding excess back into the grid or storage.

- Mechanism in action: During load shedding, the snubber’s RC network captures inductive energy from motors or inductors, routing it through a DC-DC converter for recapture. Efficiency? Up to 90% recovery rates, versus 60% in air-cooled setups.

- HVDC synergies: In renewable-integrated HVDC (e.g., solar farms feeding AI grids), this cuts PUE to under 1.2. Imagine a 1MW rack: Without recovery, braking losses alone could waste 50kWh daily. With a SiC-based Snubber liquid-cooled resistor, that’s recouped as grid power, slashing costs by 20-30% annually.

Case in point: Prototypes from Wolfspeed (Cree) in 2025 HVDC testbeds show 15% system stability gains, aligning perfectly with NVIDIA’s 2027 1MW deployment roadmap. For electric vehicle fast-charging stations—another HVDC frontier—these resistors enable bidirectional V2G (vehicle-to-grid) flows, recovering braking energy from fleets.

Advantages and Future Outlook for Snubber Liquid-Cooled Resistors

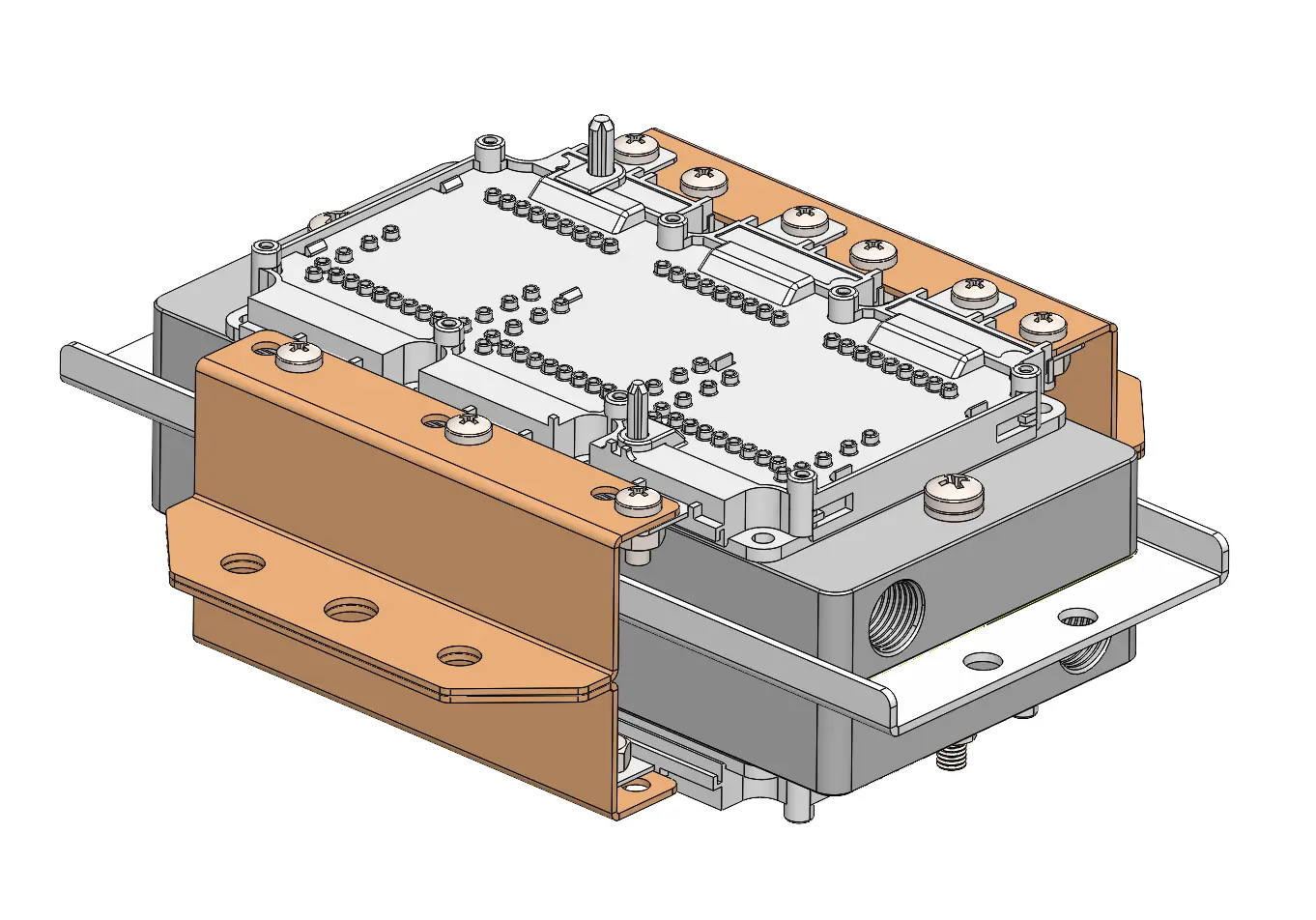

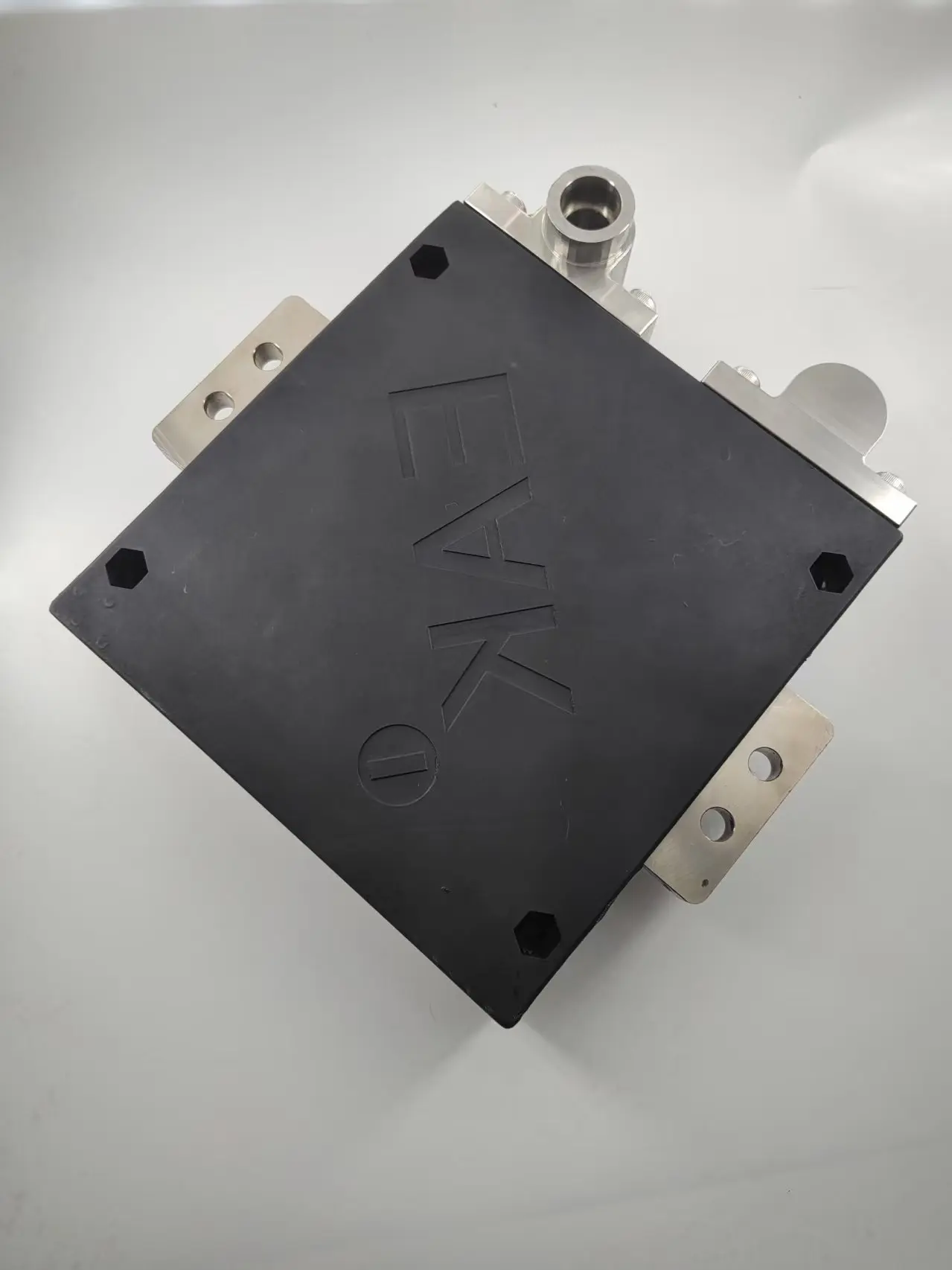

Snubber Liquid-Cooled Resistors

Snubber Liquid-Cooled Resistors

Adopting Snubber liquid-cooled resistors isn’t without challenges—initial integration costs and fluid management add complexity—but the ROI is compelling:

| Benefit | Impact in HVDC Systems |

|---|---|

| Thermal Efficiency | 2-3x higher power density; PUE <1.2 |

| Durability | TCR <25ppm; lifespan +50% vs. air-cooled |

| Sustainability | 90%+ energy recovery; 45% less copper |

| Scalability | Modular for 100kW-1MW racks |

Looking ahead to 2030, as HVDC scales for “green AI,” the global liquid-cooled resistor market is projected to hit $3.5B (CAGR 6.5%), driven by Asia-Pacific data booms. Innovations like IoT-monitored snubbers will enable predictive maintenance, further boosting uptime.

Wrapping Up: Power Up Your HVDC with Snubber Liquid-Cooled Resistors

The Snubber liquid-cooled resistor isn’t just a component—it’s the unsung hero enabling HVDC’s braking precision and energy smarts. From taming AI workload spikes to fueling sustainable grids, its role is indispensable. Ready to integrate? Consult experts like Delta or Wolfspeed for custom SiC solutions tailored to your 800V setup.What HVDC challenges are you tackling? Drop a comment below—let’s geek out on power tech!