In the rapidly evolving world of high-power electronics, thermal management has become one of the greatest challenges. As systems in electric vehicles, aerospace, radar, and industrial lasers demand more power in smaller footprints, traditional air-cooled resistors are reaching their physical limits. Enter the liquid-cooled resistor—a next-generation solution that is redefining what’s possible in power handling, efficiency, and miniaturization.

At the forefront of this innovation is a groundbreaking design: the diamond-based liquid-cooled resistor. By integrating advanced materials, precision thick-film technology, and high-efficiency cooling, this resistor delivers unmatched performance for ultra-high-power applications.

The Heart of the Innovation: Diamond-SiC Composite Substrate

The foundation of this new resistor is a diamond-silicon carbide (Diamond-SiC) composite substrate. Diamond, known for its exceptional thermal conductivity (up to 2000 W/m·K), serves as the ultimate heat-spreading layer. When combined with SiC—a material already widely used in power semiconductors for its thermal stability and electrical insulation—the result is a mechanically robust, electrically insulating, and thermally supercharged base.

This substrate allows heat generated in the resistive layer to be extracted rapidly, minimizing hotspots and enabling operation at extreme power densities—often exceeding 50 W/cm², far beyond the capabilities of conventional ceramic-based resistors.

Precision Thick-Film Resistive Layer

On top of the diamond-SiC base, a thick-film resistive layer is applied using screen-printing and high-temperature firing techniques. Materials such as ruthenium oxide (RuO₂) or bismuth-ruthenium oxide are used to achieve precise resistance values (from ohms to megaohms) with low temperature coefficients (TCR < ±50 ppm/°C). The key challenge—achieving strong adhesion between the resistive ink and the low-reactivity diamond surface—is overcome through surface metallization (e.g., Cr/Ni/Au layers), ensuring long-term reliability under thermal cycling.

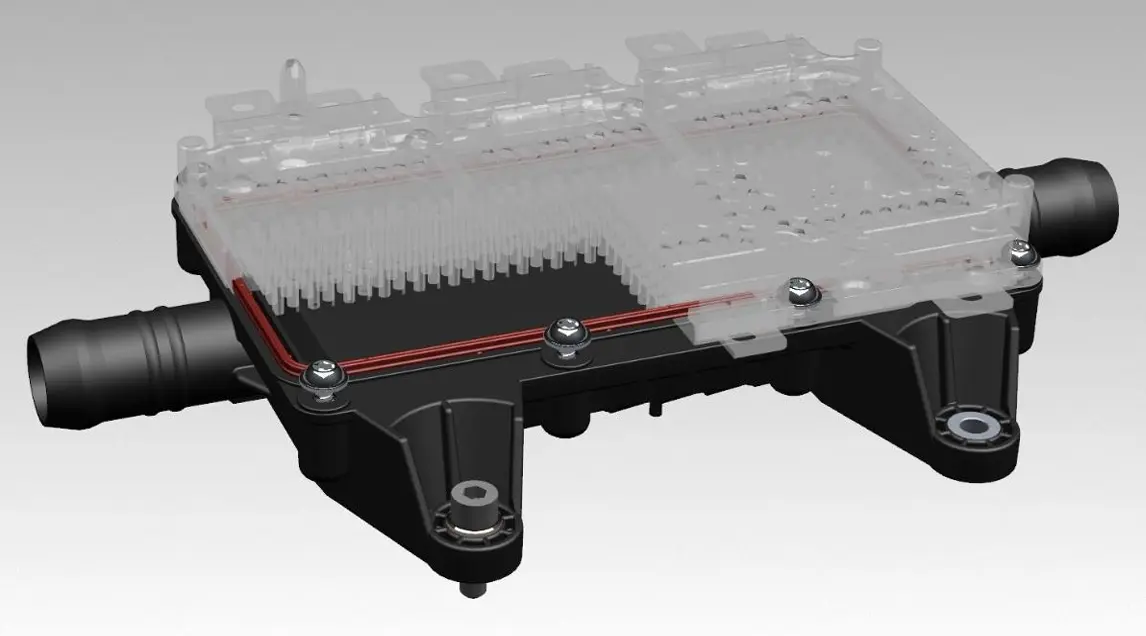

Engineered for Maximum Cooling: PIN-FIN + Liquid Cooling

What truly sets this liquid-cooled resistor apart is its integrated thermal management system. Attached to the back of the diamond substrate is a high-density copper PIN-FIN heatsink, designed to maximize surface area for heat transfer. This assembly is enclosed in a sealed liquid cooling chamber, where coolant—such as deionized water or fluorinated fluid—flows through microchannels, directly extracting heat.

This active cooling approach reduces thermal resistance to as low as 0.1–0.3 °C/W, enabling continuous operation at multi-kilowatt power levels in a remarkably compact form factor. The entire system can be 70–80% smaller than equivalent air-cooled solutions, making it ideal for space-constrained environments.

Real-World Applications

This advanced liquid-cooled resistor is already finding use in:

- Electric vehicle inverters, where it handles regenerative braking energy.

- High-power laser drivers requiring fast discharge and thermal stability.

- Military radar systems needing pulse-load termination with minimal footprint.

- Industrial power supplies and particle accelerators demanding extreme reliability.

Overcoming Challenges

Despite its advantages, the technology faces hurdles—primarily cost and manufacturing complexity. Diamond substrates remain expensive, and bonding them to metal heatsinks requires precision processes like transient liquid phase bonding or eutectic soldering. However, strategies such as localized diamond integration (only under high-heat zones) and scalable thin-film alternatives are being explored to improve cost-efficiency.

The Future is Cool—Literally

As power densities continue to rise, passive cooling will no longer suffice. The future belongs to integrated, actively cooled components, and the diamond liquid-cooled resistor is a prime example. With ongoing advances in materials science, microfluidics, and smart thermal control, we are moving toward fully intelligent, self-monitoring power modules that combine performance, reliability, and compactness.

In the race for higher efficiency and smaller size, the liquid-cooled resistor isn’t just an upgrade—it’s a revolution. And with diamond at its core, it’s also one of the toughest solutions on the market.

For engineers pushing the limits of power electronics, the message is clear: when the heat is on, go liquid-cooled.