In modern industrial and scientific fields, pulsed power supplies—serving as core units for high-energy transient output—are widely used in laser driving, electromagnetic forming, plasma generation, medical equipment, and new energy testing. These systems impose stringent demands on load components in terms of response speed, power density, and thermal stability. In this context, thick-film liquid-cooled resistors have become indispensable key components in pulsed power systems, thanks to their exceptional heat dissipation, high power handling capability, and superior electrical stability.

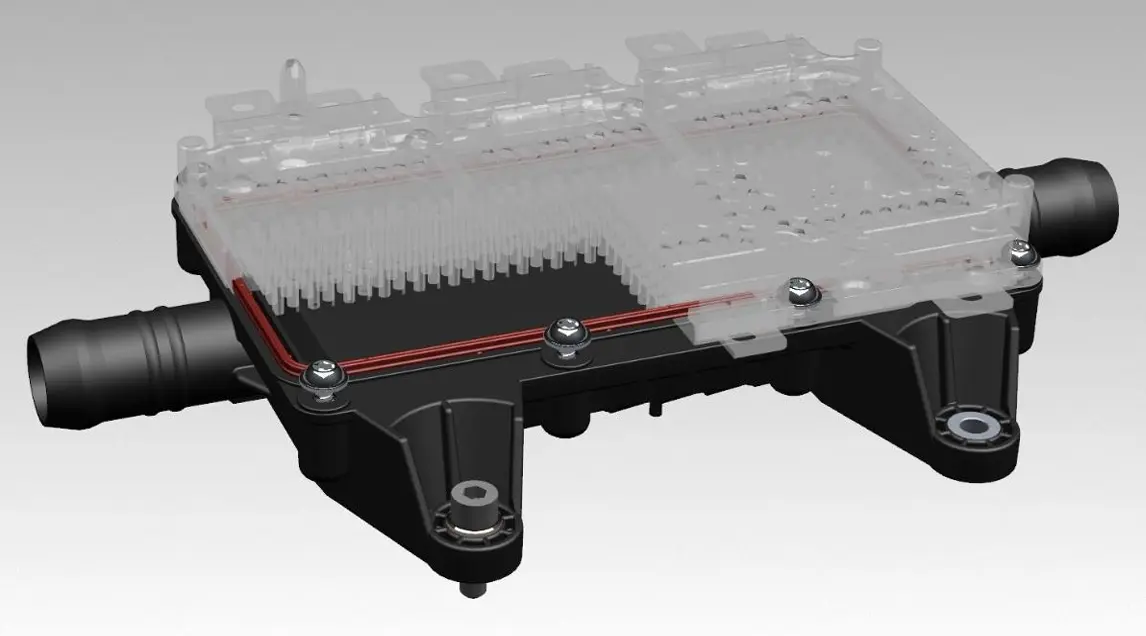

Thick-film liquid-cooled resistors utilize advanced thick-film resistive paste technology, forming a uniform and dense resistive layer on a high-thermal-conductivity ceramic substrate. Precise resistance values are achieved through laser trimming. This structural design not only ensures extremely low inductance—making it ideal for high-frequency and fast-rise-time pulse applications—but also maintains stable resistance under instantaneous high-current surges, preventing system instability caused by thermal drift. More importantly, the resistor integrates a liquid cooling channel, enabling circulating coolant to directly remove high-density heat loads. This effectively addresses the issues of overheating and short lifespan commonly seen in traditional air-cooled resistors under high-power pulsing conditions.

In practical pulsed power applications, the load often needs to absorb or dissipate large amounts of energy within extremely short durations. For example, in certain laser pulse power systems, output voltages can reach hundreds of volts with pulse widths in the millisecond range, yet peak power exceeds 10kW. Under such conditions, conventional resistors rapidly overheat due to insufficient thermal capacity, leading to cracking or resistance drift. In contrast, a multi-tap adjustable load system built with thick-film liquid-cooled resistors can withstand high-energy transients while enabling precise load matching and dynamic regulation. For instance, an 11-tap liquid-cooled resistor design can achieve a total power capacity of up to 15.7kW, with minimum resistance as low as 80Ω per tap, supporting continuous pulsed currents exceeding 25A—fully meeting the demands of complex operating conditions.

Moreover, thick-film liquid-cooled resistors offer excellent environmental adaptability and long-term reliability. Their fully sealed construction prevents coolant leakage and ensures high dielectric strength, making them suitable for harsh industrial environments such as high humidity and dusty conditions. The modular design also facilitates system integration and maintenance, supporting parallel expansion for even higher power requirements.

In summary, thick-film liquid-cooled resistors, with their combination of high power handling, stability, efficient cooling, and long service life, have become the ideal dynamic load solution for pulsed power systems. As high-energy pulse technologies continue to advance, thick-film liquid-cooled resistors will play an increasingly critical role in a broader range of high-end applications, driving power electronic systems toward higher performance and greater reliability.