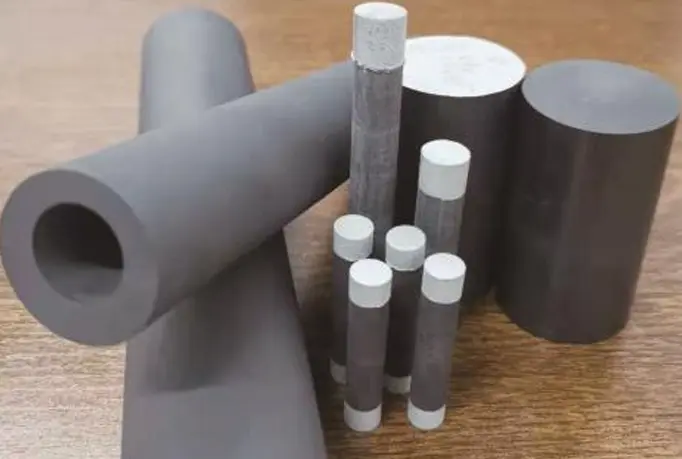

Unlock Superior Performance with SiC Ceramic ResistorsIn the fast-evolving world of power electronics, high-frequency, high-power, and high-pulse applications demand components that deliver exceptional performance under extreme conditions. Our SiC Ceramic Resistors, crafted from advanced Silicon Carbide (SiC) materials, are engineered to meet these challenges with unmatched reliability, efficiency, and durability. Designed for cutting-edge industries such as telecommunications, aerospace, electric vehicles (EVs), and renewable energy, these resistors redefine performance standards for high-frequency and high-power systems.Why Choose SiC Ceramic Resistors?Silicon Carbide (SiC) is a wide-bandgap semiconductor renowned for its superior electrical and thermal properties. With a bandgap of 3.23 eV (4H-SiC), breakdown field strength of ~3 MV/cm, and thermal conductivity up to 490 W/m·K, SiC outperforms traditional materials like silicon or metal oxides. Our SiC Ceramic Resistors leverage these properties to deliver:

- High-Frequency Performance: Optimized for frequencies up to 14 GHz, ideal for RF amplifiers, 5G infrastructure, and radar systems.

- High-Power Capability: Low on-resistance (as low as 0.02 Ω·cm²) and high power density make them perfect for power modules, EV charging stations, and photovoltaic inverters.

- High-Pulse Endurance: Engineered to withstand high-voltage pulses (up to 10 kV), ensuring reliability in surge protection and pulse power applications.

- Extreme Temperature Stability: Operates seamlessly at temperatures exceeding 800°C, suitable for aerospace and industrial furnaces.

Advanced Manufacturing for Precision and ConsistencyOur SiC Ceramic Resistors are produced using state-of-the-art sintering processes, including liquid-phase sintering and flash sintering, to achieve unparalleled material density and electrical performance. Key manufacturing features include:

- Vacancy Design: Precise control of carbon (V_C) and silicon (V_Si) vacancies enhances conductivity while minimizing leakage current. This ensures resistors maintain stable resistance (10^{-2} to 10^2 Ω·cm) under high-frequency and high-pulse conditions.

- Doping Optimization: Nitrogen (n-type) or aluminum (p-type) doping, with concentrations of 10^{16}-10^{18} cm^{-3}, tailors resistivity to meet specific application needs, from linear to nonlinear characteristics.

- Flash Sintering Technology: Utilizing pyrolytic carbon (PyC) bridges, our flash sintering process achieves densification in seconds, reducing porosity to ~15% and boosting Vickers hardness to 19.62 GPa.

- Low Defect Density: Advanced processes minimize micropipe defects (<10^4 cm^{-2}), ensuring high-voltage reliability and consistent performance.

These techniques result in resistors with superior mechanical strength, low thermal resistance (<0.5 K/W junction-to-case), and exceptional durability, even in the most demanding environments.Applications Across IndustriesOur SiC Ceramic Resistors are designed to excel in high-stakes applications:

- Telecommunications: Support 5G base stations and high-frequency RF circuits with minimal signal loss and high power handling.

- Electric Vehicles (EVs): Enable efficient power conversion in EV chargers and inverters, reducing energy loss by up to 20% compared to silicon-based components.

- Renewable Energy: Enhance reliability in solar and wind power systems, withstanding high-pulse surges and extreme temperatures.

- Aerospace and Defense: Provide robust performance in radar systems, satellite electronics, and high-pulse weaponry, operating reliably at high altitudes and temperatures.

- Industrial Systems: Ideal for high-power motor drives and furnaces, where thermal stability and pulse endurance are critical.

Key Specifications

- Resistivity Range: 10^{-2} to 10^2 Ω·cm, customizable via doping and vacancy engineering.

- Frequency Response: Up to 14 GHz (MESFET-compatible).

- Voltage Rating: 1200 V to 10 kV, ideal for high-pulse applications.

- Thermal Conductivity: ~400-500 W/m·K for superior heat dissipation.

- Operating Temperature: -55°C to 800°C.

- Porosity: <5% (liquid-phase sintering) or ~15% (flash sintering).

- Hardness: Up to 19.62 GPa for enhanced durability.

Why Partner with Us?

- Customization: Tailored resistance values, sizes, and configurations to meet your specific needs.

- Reliability: Rigorous quality control and defect minimization ensure consistent performance.

- Innovation: Cutting-edge flash sintering and vacancy design deliver industry-leading efficiency.

- Sustainability: Energy-efficient manufacturing reduces environmental impact.

Take Your Systems to the Next LevelWhether you’re designing next-generation 5G networks, high-efficiency EV powertrains, or robust aerospace systems, our SiC Ceramic Resistors provide the performance edge you need. With low conduction losses, high-pulse endurance, and unmatched thermal stability, they empower your applications to operate at peak efficiency.Contact us today to explore how our SiC Ceramic Resistors can elevate your high-frequency, high-power, and high-pulse systems.