In the field of power generation, ensuring the performance, reliability, and stability of high-power diesel generators is critical. To achieve this, manufacturers and operators rely on comprehensive testing procedures that simulate real-world operating conditions. One of the most effective tools for such testing is the liquid-cooled load resistor. This advanced solution allows for precise simulation of various load levels while efficiently dissipating heat, making it an indispensable component in generator testing applications.

Why Use a Liquid-Cooled Load Resistor?

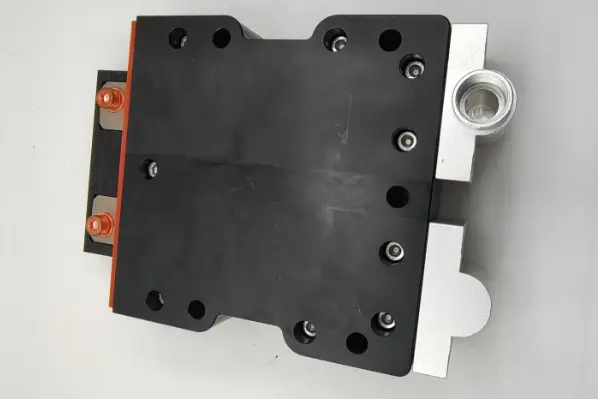

When testing large diesel generators, it is essential to replicate actual load scenarios to evaluate their output characteristics, efficiency, and stability. Traditional air-cooled resistors often struggle with heat dissipation during prolonged or high-power tests, leading to overheating and potential damage. In contrast, **liquid-cooled load resistors** offer superior thermal management capabilities. By utilizing a liquid coolant system, these resistors can absorb and dissipate the massive amounts of heat generated during energy conversion without compromising performance.

The ability to handle continuous high-power loads makes liquid-cooled load resistors ideal for rigorous generator testing. They ensure uninterrupted operation, even under extreme conditions, allowing engineers to collect accurate data on generator performance across different load profiles.

Simulating Real-World Loads

One of the standout features of liquid-cooled load resistors is their versatility in simulating diverse load levels. Whether testing a generator at 50% capacity or pushing it to its maximum output, these resistors provide consistent and reliable load absorption. The electrical energy produced by the generator is converted into thermal energy within the resistor and then efficiently removed via the liquid cooling system. This ensures stable operating temperatures throughout the test duration, preventing overheating issues that could skew results.

For example, consider a manufacturer producing 2 MW diesel generators for industrial use. Before deployment, each unit must undergo extensive testing to confirm compliance with specifications. Using a liquid-cooled load resistor, technicians can gradually increase the load from idle to full capacity, monitoring parameters such as voltage regulation, frequency stability, fuel consumption, and harmonic distortion. These metrics are crucial for assessing the generator’s overall performance and identifying any potential faults or inefficiencies.

Benefits of Liquid Cooling Technology

The integration of liquid cooling technology sets these resistors apart from conventional alternatives. Liquid coolants have significantly higher heat transfer coefficients compared to air, enabling faster and more efficient heat removal. As a result, the resistor maintains optimal operating temperatures even during extended testing sessions. Additionally, the compact design of liquid-cooled systems reduces space requirements, making them suitable for both laboratory environments and field installations.

Another advantage is enhanced durability. Since the liquid cooling system minimizes thermal stress on internal components, the lifespan of the resistor is extended. This translates to lower maintenance costs and reduced downtime, which are particularly important in mission-critical applications where generator reliability is paramount.

Conclusion

The application of liquid-cooled load resistors in generator testing represents a significant advancement in the industry. Their ability to simulate varying load conditions while maintaining efficient heat dissipation ensures accurate and reliable performance evaluations. For manufacturers and operators of high-power diesel generators, investing in this technology not only improves testing accuracy but also enhances operational safety and longevity.

By leveraging the benefits of liquid-cooled load resistors, businesses can confidently validate the performance of their generators, ensuring they meet stringent quality standards before deployment. Whether you’re conducting routine maintenance checks or developing next-generation power solutions, this innovative tool is a game-changer in the world of generator testing.