In high-performance industrial, automotive, and renewable energy systems, managing heat and energy dissipation is critical to ensuring reliability and efficiency. One effective solution is the integration of motor drivers with liquid-cooled resistors. This approach not only enhances thermal management but also improves system compactness and performance, especially in applications involving regenerative braking or high dynamic loads.

Why Integrate Motor Drivers and Liquid-Cooled Resistors?

Motor drivers control the operation of electric motors by regulating voltage and current using power semiconductors like

IGBTs or MOSFETs. During rapid deceleration or overhauling loads, motors can act as generators, feeding energy back into the DC bus—a phenomenon known as regenerative energy. If not properly managed, this energy can cause dangerous voltage spikes. A braking resistor safely dissipates this excess energy as heat.

However, in high-power systems, both the motor driver and the braking resistor generate significant heat. Traditional air cooling becomes insufficient, leading to thermal throttling or component failure. Liquid cooling offers superior heat transfer efficiency, making it ideal for compact, high-density systems. By integrating the motor driver and a liquid-cooled resistor, engineers can centralize thermal management and optimize overall system performance.

How Is Integration Achieved?

There are several ways to integrate these components:

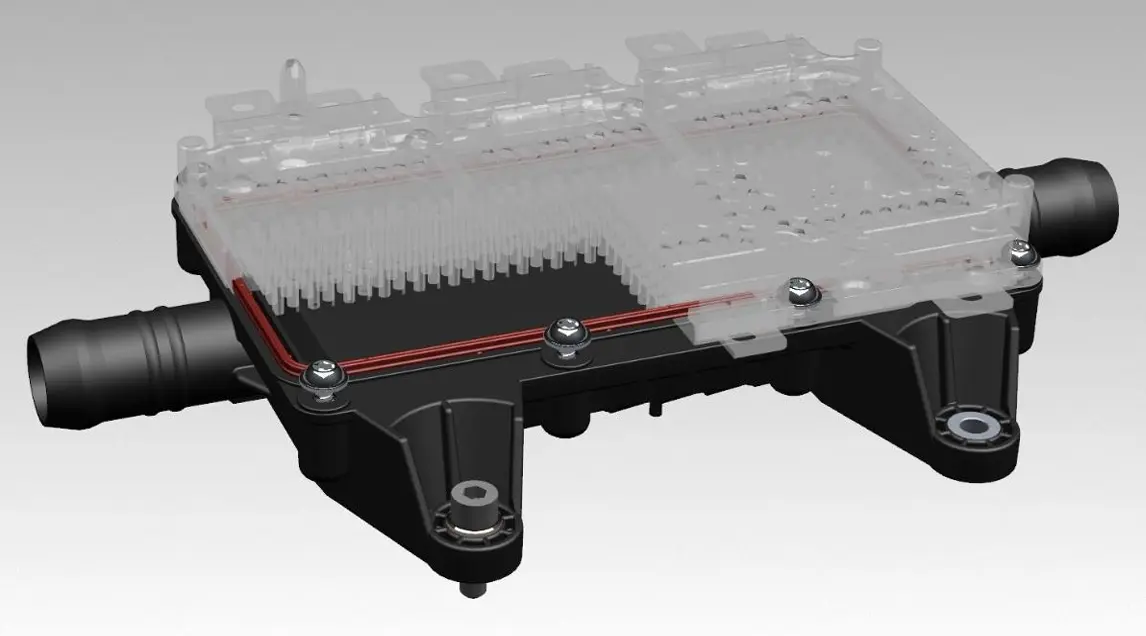

- Shared Cold Plate Design The most common method involves mounting both the driver’s power module and the braking resistor onto a single liquid-cooled cold plate. Coolant—typically a water-glycol mixture—flows through internal channels, absorbing heat from both components. This design maximizes heat transfer efficiency and minimizes footprint, making it ideal for electric vehicles and industrial servo drives.

- Integrated Liquid-Cooled Enclosure In space-constrained applications, the resistor is embedded within the driver’s housing, which doubles as a liquid-cooled structure. The coolant flows through the enclosure walls, cooling both the electronics and the resistor simultaneously.

- Common Cooling Loop Even if physically separate, the driver and resistor can share the same liquid cooling circuit. This modular approach allows flexible system layout while maintaining efficient thermal control through a centralized pump and radiator system.

Key Design Considerations

- Thermal Matching: Ensure the cooling capacity matches the combined heat load of the driver and resistor under peak and continuous operation.

- Electrical Isolation: The liquid path must be fully insulated from high-voltage components to prevent leakage or short circuits. Use of dielectric coolants or isolation layers is essential.

- Flow Optimization: Proper channel design ensures uniform coolant distribution and avoids air pockets or excessive pressure drop.

- Materials and Sealing: Aluminum cold plates are popular for their lightweight and thermal conductivity, but seals and connectors must withstand vibration and thermal cycling.

- Temperature Monitoring: Integrated sensors enable real-time thermal feedback, allowing dynamic control of switching frequency or coolant flow.

Applications and Benefits

This integration is widely used in:

- Electric Vehicles: Managing regenerative braking energy while keeping the inverter and resistor cool.

- Industrial Automation: High-dynamic servo systems with frequent start-stop cycles.

- Rail and Wind Power: Systems requiring reliable, quiet, and maintenance-free braking.

Benefits include higher power density, improved reliability, reduced noise (vs. air cooling), and longer component lifespan.

Conclusion

Integrating motor drivers with liquid-cooled resistors represents a smart fusion of power electronics and advanced thermal management. As systems grow more powerful and compact, this approach will become increasingly essential. With careful design, it delivers superior performance, efficiency, and durability—key advantages in the evolving landscape of electrified motion control.

Liquid-Cooled Resistors,Using thick-film technology with a PinFin heat sink, the power rating is 20-30 kW.

Liquid-Cooled Resistors,Using thick-film technology with a PinFin heat sink, the power rating is 20-30 kW.