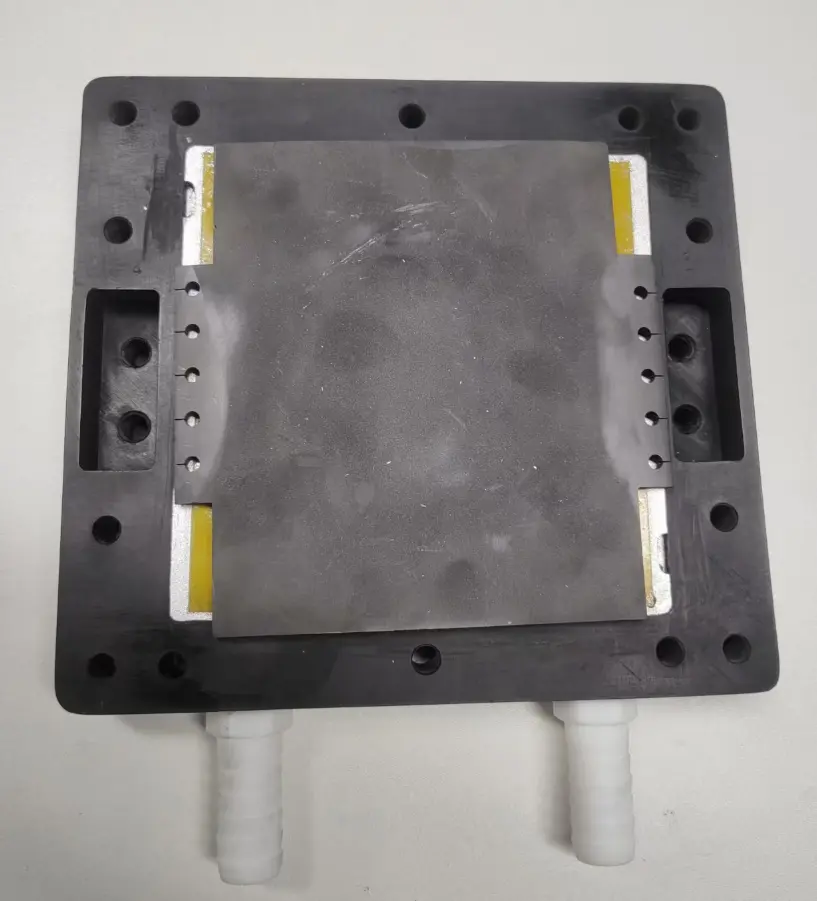

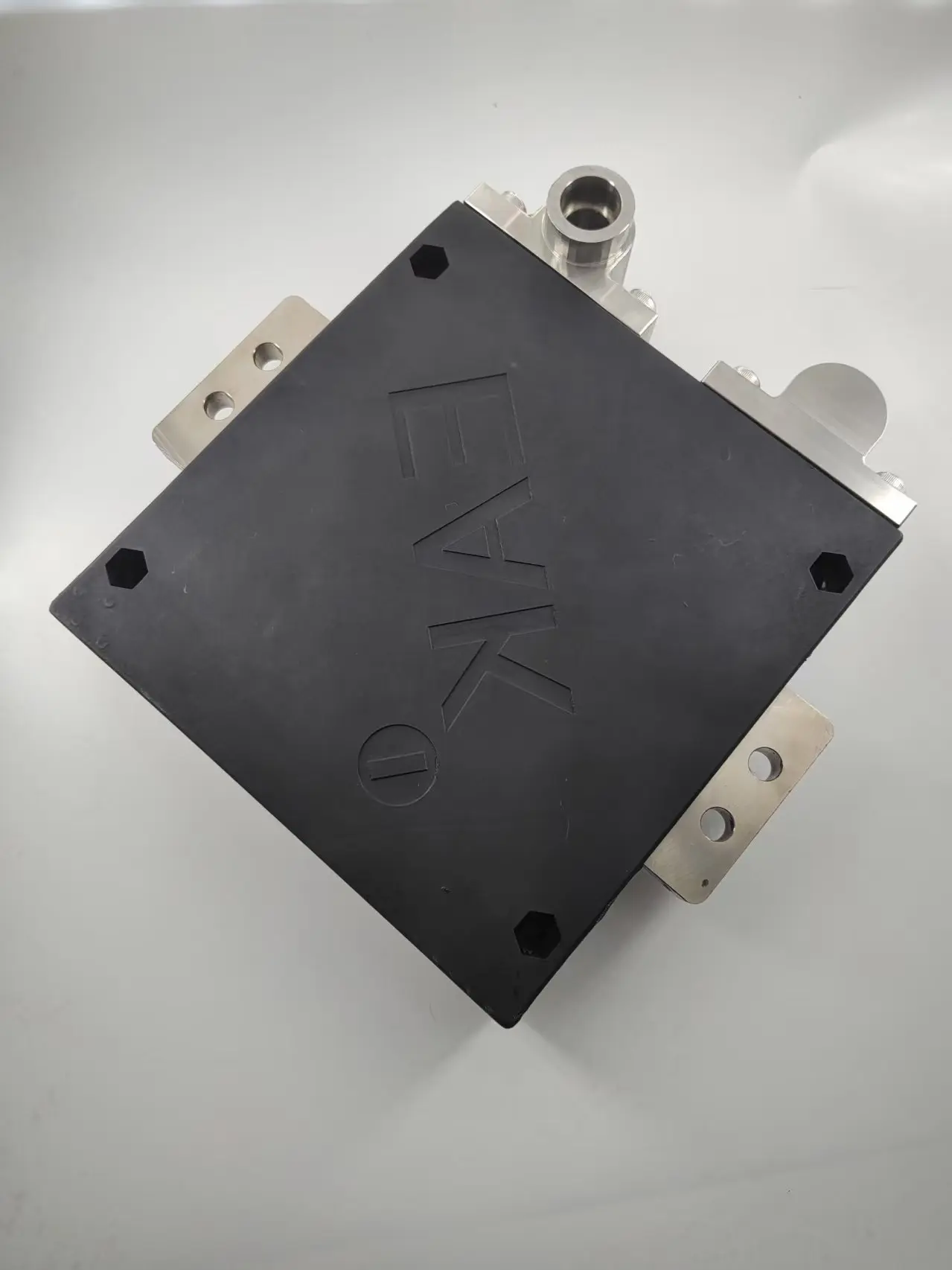

Early product images from the prototyping stage, product in R&D process

In high-power electronics — from electric vehicles and renewable energy inverters to aerospace and industrial motor drives — managing heat and maintaining stable resistance under extreme conditions is critical. Enter the double-sided water-cooled resistor, a thermal powerhouse engineered for efficiency, durability, and precision. At its heart lies the core resistive element: often a ceramic-based, defect-engineered SiC (silicon carbide) sheet, designed not just to resist — but to intelligently regulate — electrical energy under punishing thermal loads.

Why SiC Ceramic? The Material Advantage

Traditional resistive materials like metal alloys or thick-film pastes degrade rapidly above 300°C. In contrast, silicon carbide (SiC) ceramic resistors thrive in high-temperature, high-voltage, and high-power environments. With a wide bandgap (~3.2 eV), ultra-high thermal conductivity (>120 W/m·K), and exceptional chemical stability, SiC can operate continuously at 600–800°C — even surviving short bursts beyond 1000°C.

But pure SiC is naturally insulating. To transform it into a precision resistive element, engineers turn to vacancy defect engineering — a materials science technique that manipulates atomic-scale voids in the crystal lattice to precisely tune electrical resistivity.

Vacancy Design: Tuning Resistance at the Atomic Level

In SiC, two key point defects dominate resistive behavior:

- Carbon vacancies (VC) — act as p-type acceptors, lowering resistivity by generating holes.

- Silicon vacancies (VSi) — often act as carrier traps or recombination centers, increasing resistivity.

By controlling the concentration and ratio of these vacancies through high-temperature annealing in tailored atmospheres (e.g., Si-rich or C-rich), manufacturers can “dial in” target resistivity values — from 10-2 Ω·cm for low-resistance shunts to 104 Ω·cm for precision high-value resistors.

This atomic-level tuning, combined with geometric design (length × width × thickness), allows engineers to produce custom resistance values with ±1% tolerance, even under thermal stress.

Manufacturing: From Slurry to Smart Sheet

The core resistive element is typically fabricated using tape casting, a scalable, high-precision ceramic forming process ideal for thin, large-area sheets. Here’s how it works:

- Slurry Preparation: Ultrafine SiC powder is mixed with sintering aids (e.g., B₄C, AlN), dispersants, binders, and plasticizers in non-aqueous solvents.

- Tape Casting: The slurry is doctor-bladed onto a carrier film, dried, and peeled off as a flexible “green tape.”

- Cutting & Stacking: Sheets are laser-cut to size; multiple layers can be laminated for thicker elements.

- Sintering: Fired at 1900–2000°C under inert atmosphere to achieve >98% density.

- Vacancy Engineering: Annealed in controlled Si/C vapor atmospheres to fine-tune resistivity.

- Metallization: Ohmic contacts (e.g., Ni/Ti/Au or TaSi₂) are screen-printed and fired onto both sides.

- Laser Trimming (optional): For ultra-high precision, laser ablation fine-tunes final resistance.

Integration into Double-Sided Water-Cooled Assemblies

The finished SiC resistive sheet is sandwiched between two water-cooled metal plates (typically copper or aluminum with microchannel cooling). Direct contact on both sides enables:

- Ultra-efficient heat extraction — thermal resistance as low as 0.05°C/W.

- Symmetrical thermal expansion — minimizing mechanical stress.

- High power density — capable of handling >100 W/cm² continuously.

This design eliminates hot spots, extends service life, and enables operation in sealed or explosive environments — where air cooling is impossible.

Applications & Future Outlook

Double-sided water-cooled SiC resistors are revolutionizing:

- EV fast-charging systems — as pre-charge and discharge resistors.

- Wind/solar inverters — for dynamic braking and snubber circuits.

- Rail traction systems — managing regenerative energy.

- Pulsed power & defense — absorbing high-current surges without failure.

Looking ahead, integration with embedded sensors (temperature, strain) and AI-driven resistance tuning via real-time vacancy control could unlock smart, self-optimizing power resistors.

Conclusion

The core resistive sheet in a double-sided water-cooled resistor is no ordinary component. It’s a masterpiece of materials science — where atomic vacancies are harnessed like dials on a control panel, turning ultra-hard ceramic into a precision electrical element. Combined with advanced manufacturing and thermal architecture, SiC-based resistive sheets are setting a new standard for reliability, efficiency, and performance in the most demanding power systems on Earth — and beyond.

Packaged liquid-cooled resistor

Packaged liquid-cooled resistor