In the realm of high-power electronics, a reliable and efficient water-cooled resistor is essential for managing heat dissipation while maintaining optimal performance. Designed to meet the demands of modern industrial applications, our state-of-the-art double-sided water-cooled resistor integrates cutting-edge materials and innovative cooling technologies to deliver exceptional performance at power ratings ranging from 30 to 50 kW. With adjustable resistance values and robust construction, this product stands as a benchmark in the field of water-cooled resistors .

Superior Design with Silicon Carbide Ceramic Core

At the heart of this water-cooled resistor lies its unique snake-shaped silicon carbide (SiC) conductive ceramic core. Silicon carbide is renowned for its excellent thermal conductivity, high-temperature stability, and resistance to wear and corrosion. These properties make it ideal for handling extreme electrical loads without compromising efficiency or longevity. The snake-like design of the core ensures uniform current distribution, reducing hotspots and enhancing overall reliability. This core technology not only supports ultra-high power levels but also allows for precise adjustment of resistance values, catering to diverse application requirements.

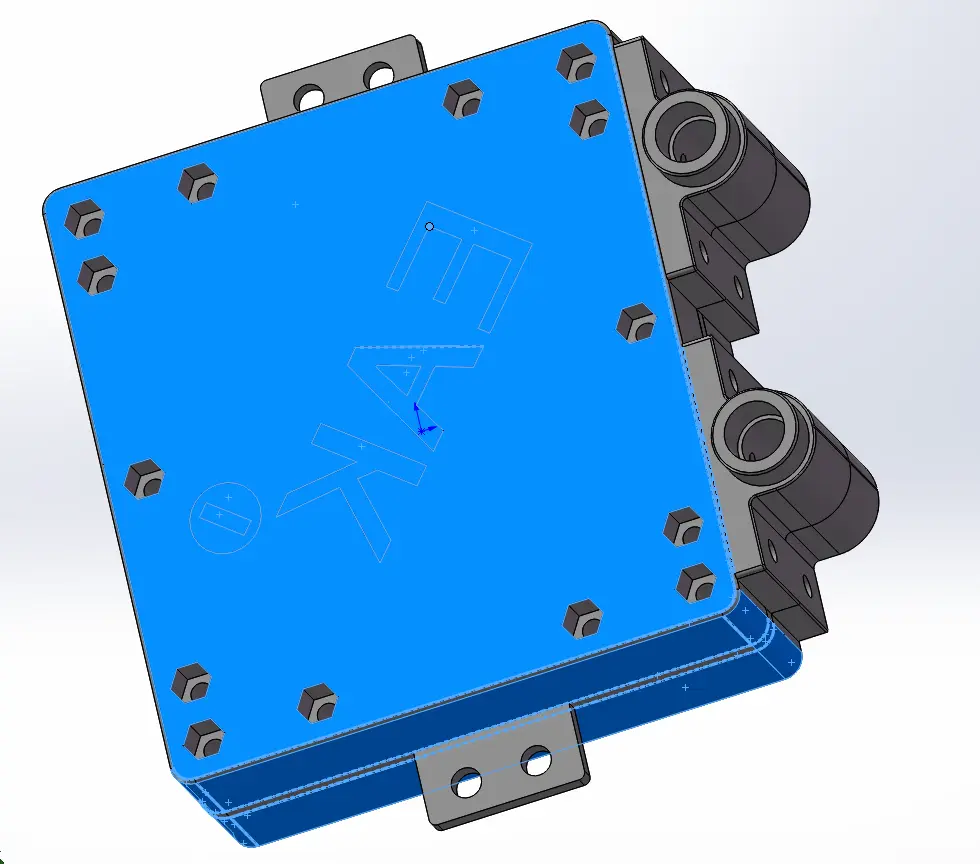

Double-Sided PINFIN Liquid Cooling System

To manage the immense heat generated during operation, this water-cooled resistor employs a double-sided PINFIN liquid cooling system on both surfaces of the device. The PINFIN design maximizes surface area contact between the coolant and the resistor housing, enabling superior heat transfer capabilities. By incorporating two independent cooling channels, the system effectively dissipates heat from both sides of the resistor simultaneously, ensuring stable operating temperatures even under heavy load conditions. This advanced cooling mechanism significantly extends the lifespan of the resistor and enhances its operational safety.

Leak-Proof Construction with Vacuum Brazing Technology

One of the critical challenges in designing water-cooled resistors is preventing coolant leakage, which can lead to catastrophic failures. Our solution addresses this issue through the use of vacuum brazing technology during manufacturing. This process creates an airtight seal between the metal components and the ceramic core, eliminating any risk of fluid leaks. Vacuum brazing ensures that the internal structure remains hermetically sealed, providing long-term durability and peace of mind for users operating in demanding environments.

Versatile Applications Across Industries

The versatility of this water-cooled resistor makes it suitable for a wide range of industries and applications. It excels in scenarios requiring dynamic braking, load testing, energy absorption, and motor control systems. For instance, in renewable energy systems such as wind turbines and solar inverters, these resistors play a crucial role in converting excess energy into heat safely. Similarly, they are indispensable in electric vehicle testing rigs, industrial machinery, and power generation facilities where precision and reliability are paramount.

Why Choose Our Water-Cooled Resistor?

- High Power Capacity: Capable of handling up to 50 kW, this resistor meets the needs of the most demanding applications.

- Adjustable Resistance: Offers customizable resistance values, allowing users to tailor the device to their specific requirements.

- Efficient Cooling: The double-sided PINFIN cooling system ensures rapid heat dissipation, minimizing downtime and maintenance costs.

- Robust Build Quality: Vacuum brazing guarantees leak-free operation, making the resistor highly durable and reliable.

- Compact Design: Despite its high power rating, the resistor features a compact footprint, saving valuable space in installations.

Conclusion

When it comes to selecting a water-cooled resistor , there’s no room for compromise. Our double-sided water-cooled resistor combines advanced materials like silicon carbide ceramic cores with innovative cooling technologies to provide unmatched performance and reliability. Whether you’re working in renewable energy, automotive testing, or heavy industry, this resistor is engineered to exceed your expectations. Invest in a solution that delivers consistent results, minimizes maintenance, and maximizes efficiency—choose our water-cooled resistor today.

For more information about our products and how they can benefit your operations, contact us now. Experience the difference that superior engineering and meticulous craftsmanship can make in your high-power applications.