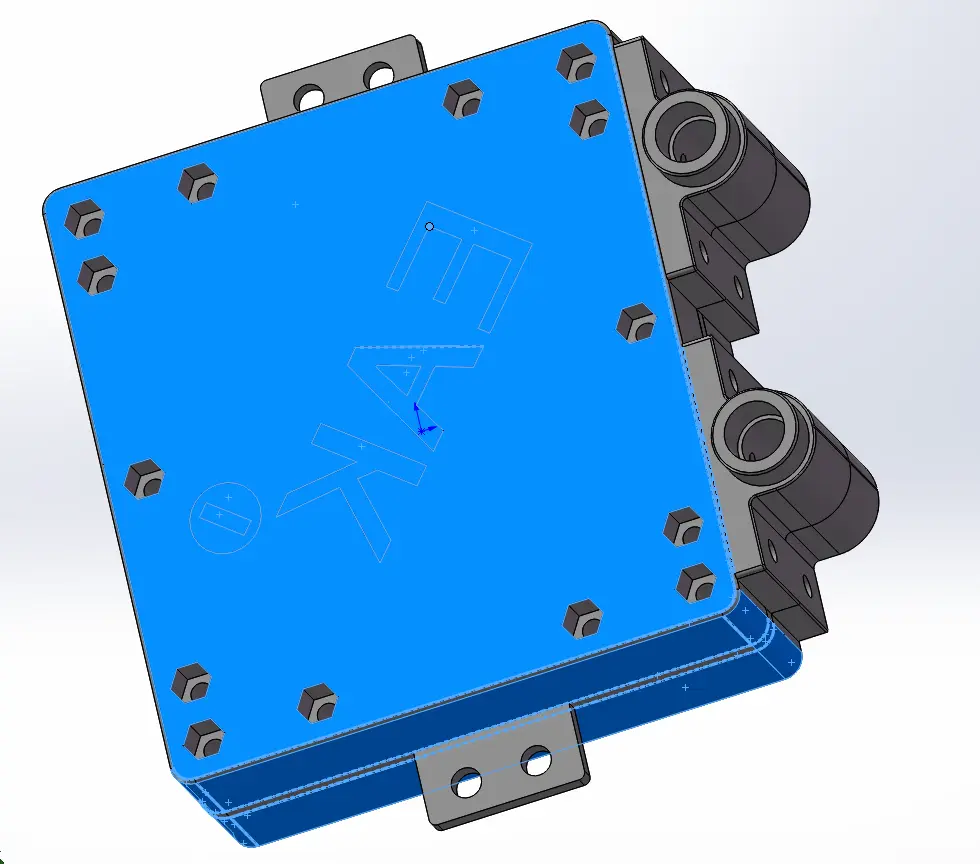

In today’s rapidly advancing industrial landscape, precision and reliability are paramount when it comes to electrical components. Among these, water-cooled resistors have emerged as a cornerstone technology for managing high-power applications efficiently. EAK, a leader in innovative resistor solutions, has introduced a cutting-edge water-cooled resistor that combines advanced materials, intelligent design, and superior performance. This product is engineered to meet the needs of industries requiring robust, high-power resistive solutions.

Advanced Design for Superior Performance

At the heart of EAK’s water-cooled resistor lies a porous silicon carbide resistive core , renowned for its excellent thermal conductivity and durability. Silicon carbide is highly resistant to thermal shock and wear, making it an ideal material for applications involving extreme temperatures and heavy loads. The porous structure enhances heat dissipation, ensuring consistent performance even under demanding conditions.

One standout feature of this resistor is its serpentine circuit design , which eliminates inductance. Inductance can cause voltage spikes and other undesirable effects in high-frequency applications. By adopting a non-inductive design, EAK ensures stable operation across a wide range of frequencies, making the resistor suitable for both DC and AC systems.

High Current Capacity with Efficient Heat Management

EAK’s water-cooled resistor is built to handle super-high currents , thanks to its large-area copper busbar terminals . These terminals provide low-resistance connections, minimizing energy loss and maximizing efficiency. Whether you’re dealing with 45KW or scaling up to 60KW, this resistor delivers reliable performance without overheating or degrading over time.

Heat management is further enhanced by the use of silicon nitride ceramic substrates for insulation. Silicon nitride is known for its exceptional mechanical strength and electrical insulation properties. It acts as a barrier between the resistive element and the cooling system, ensuring safe and efficient operation. Additionally, the resistor incorporates dual-sided PINFIN liquid cooling plates that facilitate heat dissipation from both the top and bottom surfaces. This dual-sided approach significantly improves thermal efficiency, allowing the resistor to maintain optimal operating temperatures even during prolonged use.

Versatile Resistance Range for Custom Applications

Flexibility is another hallmark of EAK’s water-cooled resistor. With adjustable resistance values ranging from 10Ω to 1000Ω , this product caters to a broad spectrum of industrial requirements. Whether you need precise control over lower resistance levels or higher impedance for specialized tasks, this resistor offers unparalleled adaptability. Its ability to operate at power ratings up to 60KW makes it an excellent choice for applications such as dynamic braking systems, load testing, harmonic filtering, and more.

Why Choose EAK Water-Cooled Resistors?

When selecting a water-cooled resistor, reliability, efficiency, and longevity are critical factors. EAK’s commitment to quality is evident in every aspect of their design and manufacturing process. Here’s why EAK stands out:

- Durability : The combination of porous silicon carbide cores and silicon nitride ceramics ensures long-lasting performance, even in harsh environments.

- Efficient Cooling : Dual-sided PINFIN liquid cooling provides unmatched thermal management, reducing the risk of overheating and extending the lifespan of the resistor.

- Versatility : With a wide resistance range and compatibility with super-high currents, EAK’s resistors can be tailored to suit virtually any application.

- Precision Engineering : The serpentine, non-inductive circuit design guarantees stability and accuracy, making these resistors ideal for sensitive electronic systems.

Applications Across Industries

The versatility and high-performance capabilities of EAK’s water-cooled resistors make them indispensable across various sectors. Key applications include:

- Dynamic Braking Systems : In industries like rail transport and mining, where large motors require controlled deceleration, water-cooled resistors dissipate excess energy safely and efficiently.

- Load Banks : For testing generators, UPS systems, and other power equipment, these resistors provide accurate and reliable load simulation.

- Renewable Energy : As wind turbines and solar farms become more prevalent, water-cooled resistors help manage fluctuations in power generation, ensuring grid stability.

- Industrial Automation : High-power machinery and robotics benefit from the precision and reliability offered by EAK’s resistors.

Conclusion

In summary, EAK’s water-cooled resistor represents the pinnacle of modern resistor technology. Its innovative design, incorporating porous silicon carbide cores, non-inductive circuits, and dual-sided liquid cooling, sets a new standard for efficiency and reliability. Whether you’re working with 45KW or 60KW systems, or require resistance values between 10Ω and 1000Ω, this product delivers exceptional performance.

Investing in EAK’s water-cooled resistors means choosing a solution that not only meets but exceeds your expectations for power handling, thermal management, and adaptability. For industries seeking dependable, high-performance resistive solutions, EAK’s water-cooled resistors are the ultimate choice.