Water-Cooled Braking Resistors

Water-Cooled Braking Resistors

In the world of electric and hybrid-electric vehicles, as well as high-performance industrial applications, efficient energy management is key. One often-overlooked hero in this equation is the braking resistor. But not just any resistor – we’re talking about water-cooled braking resistors, a technology that’s revolutionizing how excess energy is handled, offering significant advantages over traditional air-cooled systems.

The fundamental principle of a braking resistor is to convert surplus braking energy into heat, preventing voltage spikes in the intermediate circuit when a motor acts as a generator during electric braking. This process effectively dissipates energy and slows down the motor, bringing machinery to a controlled stop. Traditional air-cooled resistors have served this purpose, but they come with inherent limitations, especially in terms of size and environmental resilience.

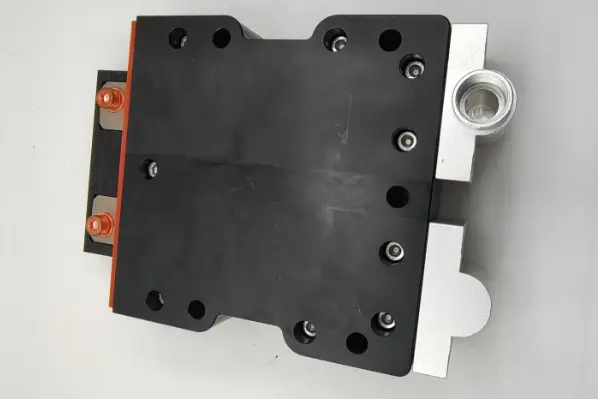

This is where water-cooled braking resistors shine. Their most striking advantage is the incredible space-saving potential – up to 90% compared to conventional air-cooled units. Imagine the design flexibility this offers for engineers working on compact electric powertrains or within tightly packed industrial machinery. This compact footprint doesn’t come at the expense of performance; in fact, these resistors deliver exceptionally high performance even in confined spaces. This makes them an ideal solution for applications where every inch matters, from the sleek chassis of an electric car to the intricate workings of a wind turbine.

Beyond just saving space, water-cooled resistors are built for the toughest conditions. Their robust design allows them to operate reliably in harsh environments, such as those exposed to salt spray. With an impressive IP 69K protection rating, these resistors are sealed against high-pressure water jets and dust, ensuring longevity and consistent performance even in challenging industrial or outdoor settings. This level of durability is crucial for maintaining operational efficiency and reducing downtime in critical applications.

The integration of these resistors is also remarkably user-friendly. Featuring drip-free quick fasteners, connecting the resistor is a straightforward and mess-free process. This seemingly small detail significantly streamlines installation and maintenance, saving time and effort for technicians.

In essence, water-cooled braking resistors are not just about dissipating energy; they are about optimizing it. By efficiently converting excess braking energy into useful heat, they protect sensitive electrical equipment from harmful voltage surges. Simultaneously, they absorb current, effectively reducing motor speed and ensuring smooth, controlled machine braking. This combination of protection and precise control makes them indispensable for the next generation of electric and hybrid drive systems, pushing the boundaries of performance and reliability.