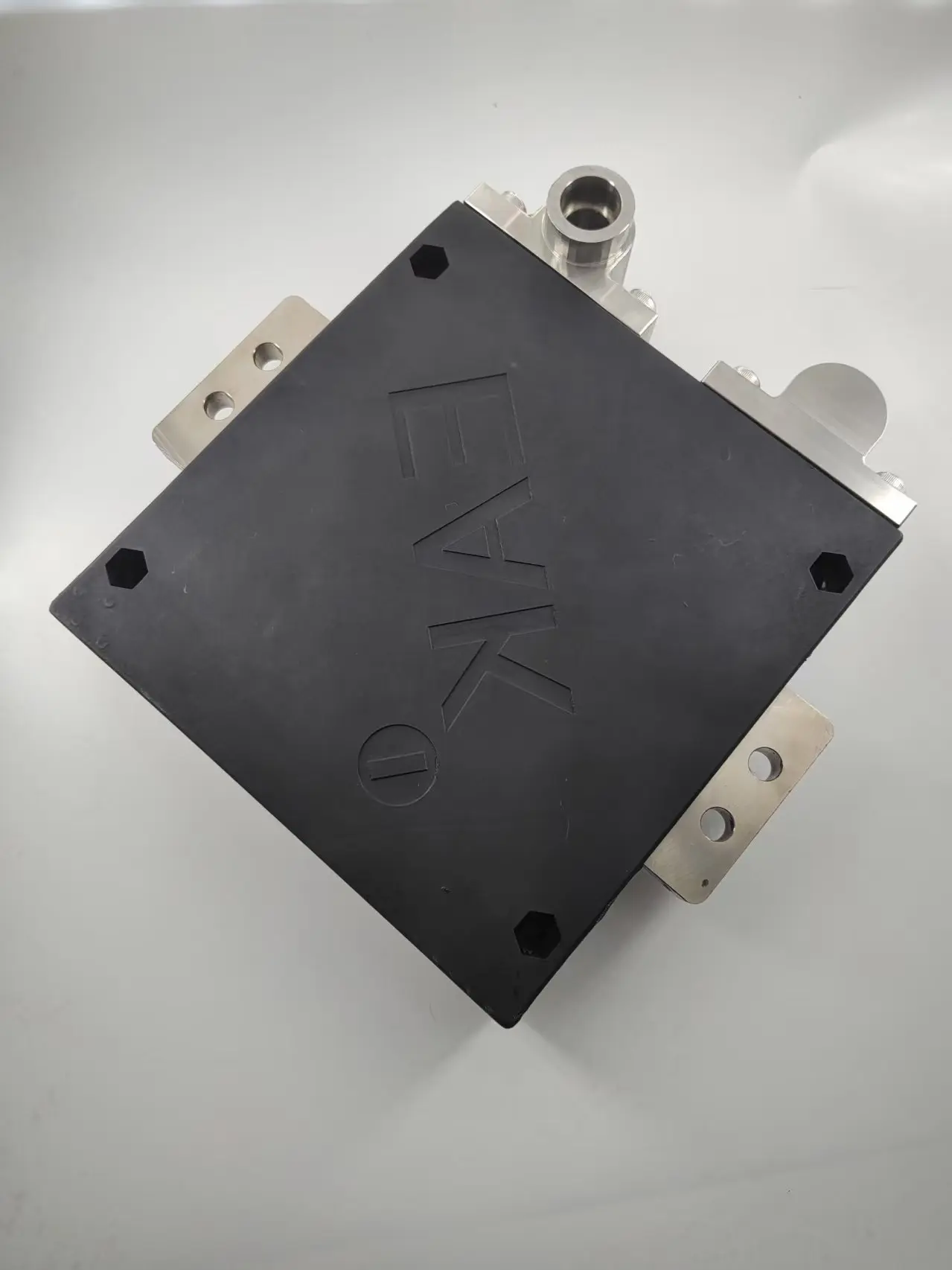

In the fast-evolving domain of sustainable transportation, EAK’s Liquid-Cooled High-Power Braking Resistors emerge as a groundbreaking solution for fuel cell and hybrid vehicles. Engineered to satisfy the strict demands of modern powertrains, these resistors provide a seamless combination of compact design, high performance, and energy efficiency, making them essential for next-generation mobility technologies.

Unsurpassed Power Handling for Advanced Vehicles

EAK’s range of liquid-cooled braking resistors covers a power spectrum from 35 kW to 150 kW, catering to various applications in fuel cell and hybrid vehicles. While optimized for braking systems, these resistors perform excellently in any high-power industrial setting with liquid-cooling infrastructure. Their sturdy design guarantees reliable operation under extreme conditions, from urban stop-and-go traffic to high-speed highway travel.

Key Technical Attributes:

- Compact and Lightweight: Constructed with a sandwich-style design, EAK resistors are notably smaller than traditional metal equivalents, facilitating easy integration into motor compartments. Weights vary from 2.0 kg to 8.5 kg—up to 50% lighter than conventional solutions—without sacrificing sturdiness.

- IP65 Protection: Enclosed in thermoplastic housings, these resistors are fully shielded against dust and water intrusion, allowing safe installation both inside and outside vehicle cabins.

- Electrical Safety: The non-conductive housing eliminates the risks of electrical short-circuits, while the design alleviates capacitance issues common in metal assemblies, ensuring stable performance even at high voltages.

- Liquid-Cooling Efficiency: Power handling is optimized through advanced thermal management, with heat dissipation depending on coolant type, temperature, and flow rate. This adaptability makes them suitable for dynamic vehicle environments.

Diverse Functions for Smart Mobility

EAK resistors are more than mere braking components—they are fundamental to comprehensive vehicle energy management:

1. Primary Braking System

When the motor shifts to generator mode during deceleration, the electronic controller links the EAK resistor to the drive motor, transforming kinetic energy into heat. This offers smooth, responsive braking while reducing wear on mechanical brake parts.

2. Downhill Speed Regulation

Through intelligent software integration, EAK resistors automatically maintain preset speeds during downhill driving. By activating the resistor in the motor’s circuit, the system prevents out-of-control acceleration, enhancing safety on steep terrain without solely relying on mechanical brakes.

3. Heat Recycling for Energy Efficiency

Rather than wasting the heat generated during braking, EAK resistors enable thermal reuse:

- Cabin Heating: Redirect waste heat to warm passenger compartments, decreasing dependence on battery-powered heaters in cold climates.

- Fuel Cell Thermal Regulation: Maintain optimal fuel cell operating temperatures by recycling heat, eliminating the need for auxiliary power to control temperature. This is especially vital for cold starts in sub-zero environments.

- Pre-Heating in Harsh Conditions: In winter, the resistor can draw power from a local source via the ECU to pre-heat the vehicle and fuel cell, ensuring comfort and operational readiness even at extremely low temperatures.

Perfect for Fuel Cell and Hybrid Applications

The EAK series tackles two major challenges in clean energy vehicles:

- Space Limitations: The compact design fits smoothly into tight motor bay layouts, a necessity for hybrid and fuel cell vehicles where space is scarce.

- Weight Reduction: The lightweight thermoplastic structure improves energy efficiency by reducing overall vehicle mass, directly boosting fuel economy and battery range.

Models and Specifications

| Model | Rated Power | Weight | Protection Class | Application Scenarios |

|---|---|---|---|---|

| EAK-35 | 35 kW | 2.0 kg | IP65 | Compact hybrid cars |

| EAK-75 | 75 kW | 4.8 kg | IP65 | Mid-size fuel cell vehicles |

| EAK-100 | 100 kW | 6.3 kg | IP65 | Heavy-duty hybrids |

| EAK-150 | 150 kW | 8.5 kg | IP65 | Commercial trucks & buses |

Future-Proof Technology

As the automotive industry transitions to electrification, EAK’s liquid-cooled resistors establish a new benchmark for reliability and sustainability. By integrating high-power performance with intelligent thermal management, they not only improve vehicle safety and efficiency but also contribute to a greener ecosystem by minimizing energy waste.

Whether you are developing the next generation of fuel cell trucks or optimizing the performance of hybrid sedans, EAK’s Liquid-Cooled High-Power Braking Resistors offer the innovation and durability required to drive the future of mobility.