In today’s rapidly evolving industrial landscape, the demand for high-performance power management solutions has never been higher. At the forefront of this technological revolution stands EAK , a trusted name in electrical components and systems. Our tubular power resistors are engineered to meet the rigorous demands of modern industries—from renewable energy systems and electric vehicle (EV) charging infrastructure to rail transport and heavy manufacturing.

Why Tubular Power Resistors Matter

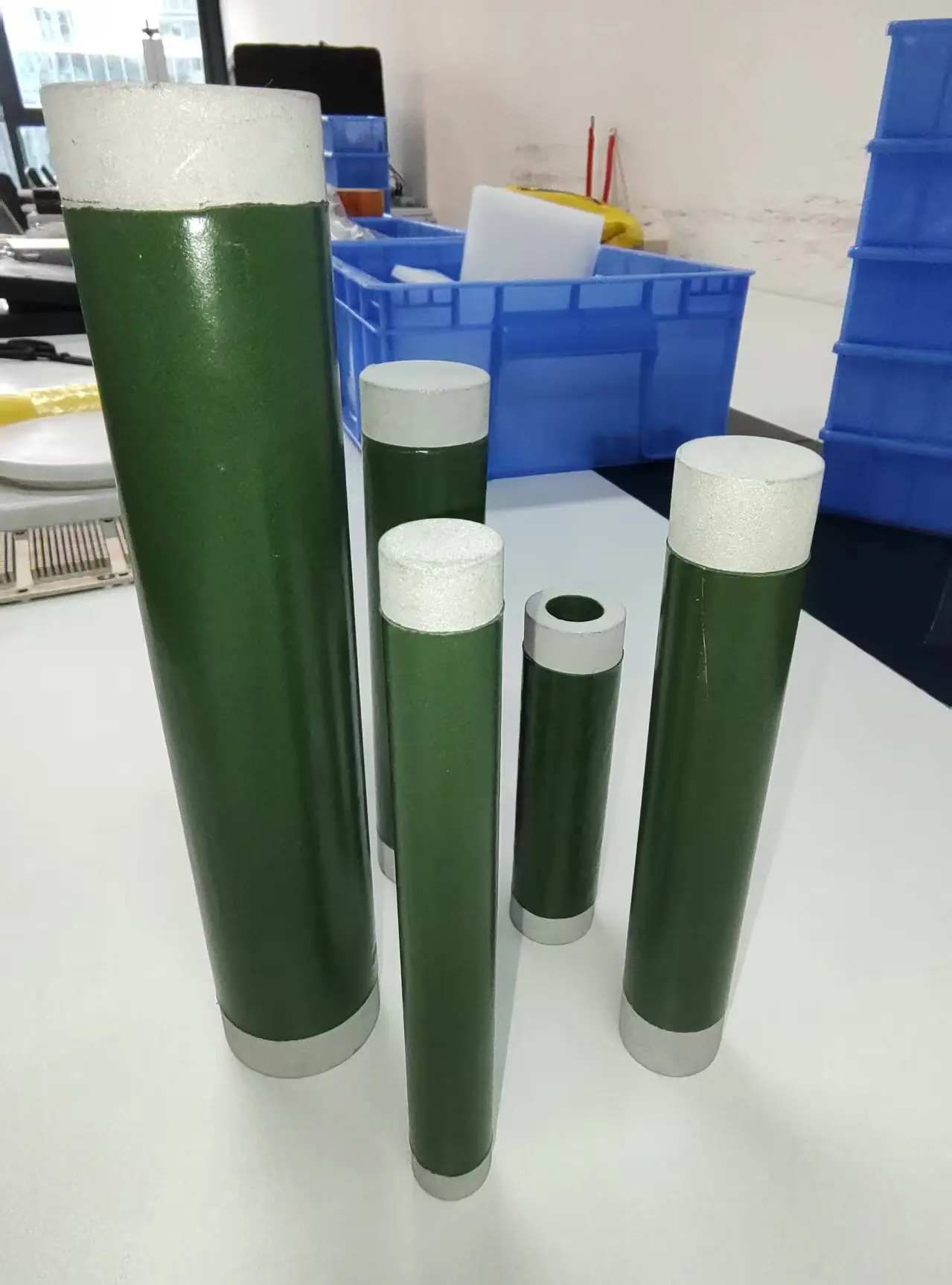

Tubular power resistors play a critical role in applications that require robust energy dissipation, precise control, and long-term reliability. These cylindrical resistive elements excel at handling high power loads while maintaining thermal stability, making them indispensable in environments where performance under pressure is non-negotiable.

From steel mills using dynamic braking systems to wind turbines protecting against voltage spikes, tubular resistors ensure safety, efficiency, and system longevity. As global markets shift toward electrification and green technologies, EAK is committed to delivering innovative resistor solutions that support these critical transitions.

Tubular Power Resistors

Tubular Power Resistors

EAK’s Commitment to Innovation and Quality

At EAK, we understand that one size does not fit all. That’s why our tubular power resistors are available in both standardized and customized configurations , tailored to meet the specific needs of each application. Whether you’re building next-generation EV fast chargers or upgrading railway traction systems, EAK offers:

- High-Power Handling : Designed to manage extreme thermal and electrical stresses.

- Superior Thermal Management : Optimized heat dissipation through advanced materials like nickel-chrome alloys and ceramic cores.

- Durability in Harsh Environments : Corrosion-resistant designs for offshore, mining, and chemical processing applications.

- Customization Capabilities : From compact units for urban transit systems to water-cooled models for ultra-high-power applications.

Our manufacturing processes incorporate proprietary winding techniques, precision laser trimming, and automated quality assurance systems—ensuring every resistor meets international standards such as IEC 60076-21, MIL-STD-202G, and RoHS compliance.

Industry-Specific Applications Driving Demand

1. Rail Transportation

With the EU targeting 75% railway electrification by 2030, EAK’s tubular resistors are integrated into traction converters and braking systems for leading manufacturers like Siemens and Alstom. Our resistors help manage regenerative braking energy, ensuring safe and efficient train operations across urban and high-speed networks.

2. Renewable Energy Systems

As the world moves toward sustainable energy, EAK supports the growth of solar farms and wind parks with robust resistance solutions. Our products provide short-circuit protection in wind turbines and DC link stabilization in solar inverters, helping companies like Vestas and GE Renewable Energy maintain grid stability and system integrity.

3. Electric Vehicle Charging Infrastructure

The global EV charging market is projected to exceed $100 billion by 2030. EAK’s high-power tubular resistors are essential in pre-charge circuits and emergency discharge systems in ultra-fast 350kW DC charging stations. With thermal stability and rapid energy dissipation, our resistors ensure safety and reliability in next-gen EV charging systems.

4. Industrial Manufacturing & Mining

From load testing in steel plants to conveyor motor controls in mining operations, EAK’s rugged tubular resistors deliver unmatched durability. We supply high-current resistors for arc furnaces, cranes, and hoisting systems—ensuring operational continuity even in the harshest conditions.

Tubular Power Resistors

Tubular Power Resistors

Sustainable Engineering Meets Market Needs

EAK recognizes the growing importance of sustainability and regulatory compliance. Our resistor designs align with the latest energy efficiency directives, including the EU EcoDesign Lot 11 and U.S. DOE guidelines , which mandate minimum efficiency thresholds. By integrating modular cooling features and thermally optimized materials, EAK delivers resistors that not only perform better but also reduce overall energy consumption—by up to 20% compared to legacy models.

We are also investing in alternative alloy development to reduce dependency on rare metals. Our aluminum-iron-silicon (AISi) resistive elements offer enhanced corrosion resistance and thermal performance, particularly suited for marine and desert environments.

Trusted by Industry Leaders Worldwide

EAK serves clients across North America, Europe, Asia-Pacific, and emerging markets like India, Brazil, and Southeast Asia. Whether it’s custom-designed resistors for defense radar systems or standardized units for HVAC and automation equipment, our global footprint ensures timely delivery and technical support wherever you need it.