What Are Diamond Thick Film Resistors?

In the world of high-power electronics—especially in electric vehicles, data centers, renewable energy inverters, and industrial test systems—thermal management is the ultimate bottleneck. Enter Diamond Thick Film Resistors: a cutting-edge hybrid solution that combines high-stability thick film resistive elements, electrically insulating diamond substrates, and ultra-efficient PinFin liquid cooling to deliver unmatched power density and reliability.

Contrary to what the name might suggest, Diamond Thick Film Resistors do not use diamond as the resistive material. Instead, they leverage synthetic CVD (Chemical Vapor Deposition) diamond as a thermally conductive, electrically insulating substrate—onto which standard thick film resistor chips are mounted. This assembly is then directly bonded to a copper PinFin heat sink, enabling direct liquid cooling for extreme heat dissipation.

This architecture is ideal for applications demanding 10 kW to 50 kW+ of continuous power handling in a compact footprint—without compromising safety or signal integrity.

Why Diamond? The Thermal Advantage

Diamond is nature’s best thermal conductor:

- Thermal conductivity: 1,000–2,200 W/m·K (vs. 170 W/m·K for AlN, 400 W/m·K for copper)

- Electrical resistivity: >10¹⁶ Ω·cm (excellent high-voltage insulation)

- Low CTE (~1 ppm/K): minimizes thermal stress during cycling

When used as a substrate beneath a thick film resistor element, diamond acts as a thermal superhighway, pulling heat away from the resistive layer before it can cause hot spots or drift. This enables:

Higher power density

Improved long-term stability

Reduced derating in high-ambient environments

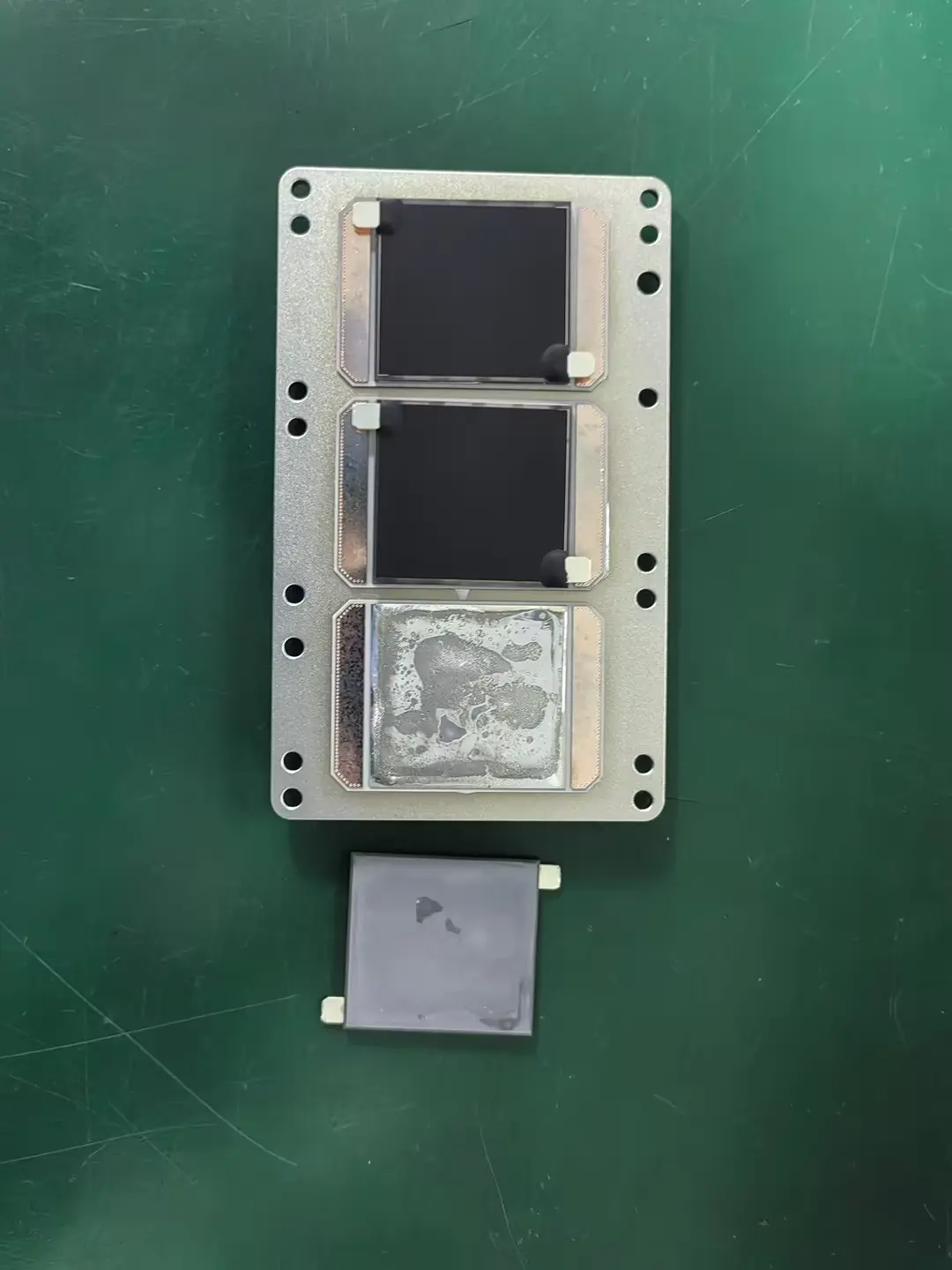

Diamond Thick Film Resistors

Diamond Thick Film Resistors

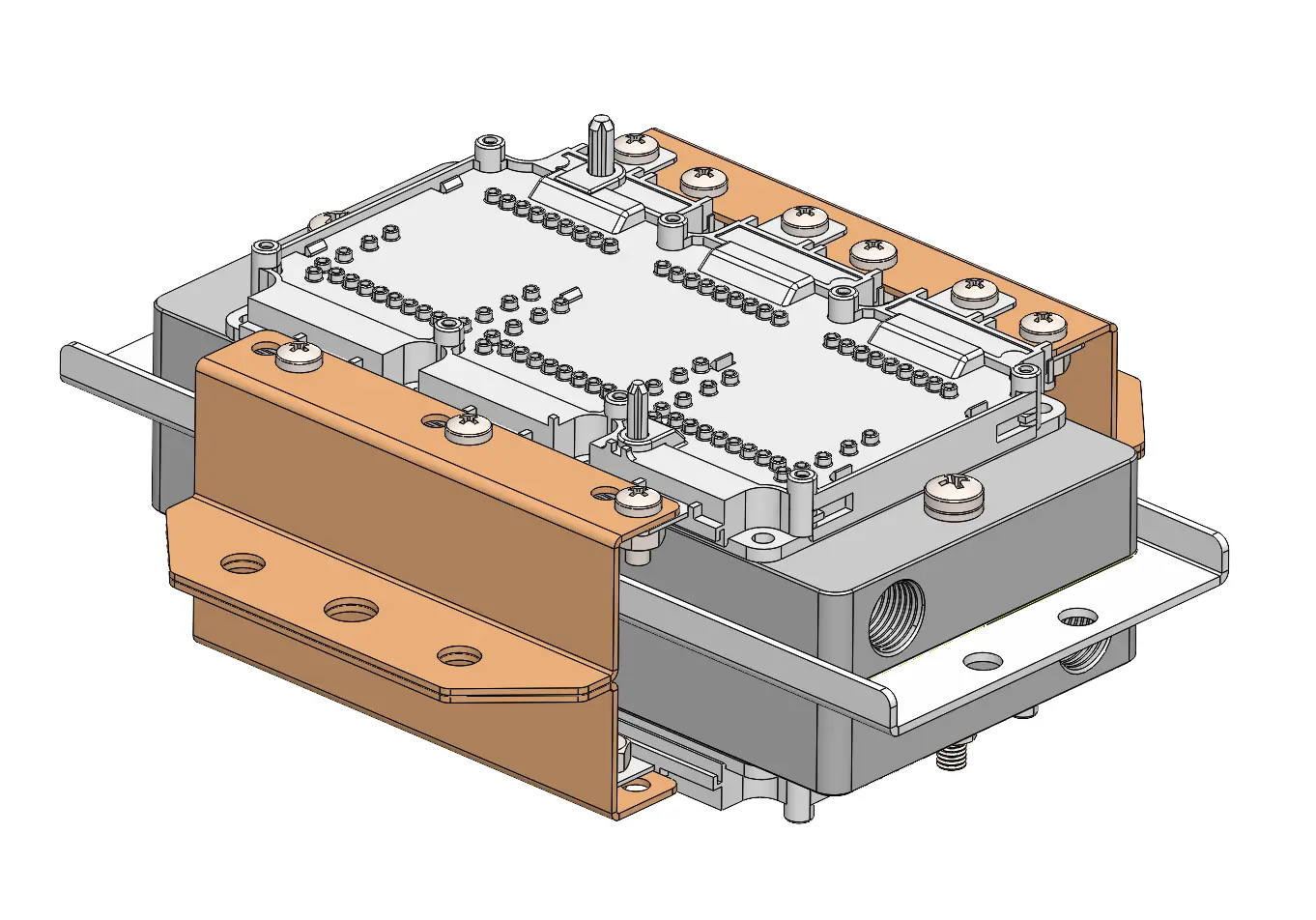

The Role of PinFin Liquid Cooling

A diamond substrate alone isn’t enough for multi-kilowatt loads. That’s where copper PinFin liquid cooling comes in.

PinFin heat sinks feature an array of pin-shaped fins that dramatically increase surface area in contact with coolant (typically deionized water or dielectric fluid). When the diamond-mounted resistor assembly is directly soldered or bonded to the PinFin base, heat flows:

Resistor → Diamond substrate → Copper PinFin → Coolant

This direct thermal path minimizes interfacial resistance and enables heat removal rates exceeding 1 kW/cm² in optimized designs.

Key benefits of PinFin integration:

- Dual-sided cooling possible (coolant flows on both sides of the resistor stack)

- Low pressure drop compared to microchannel coolers

- Leak-resistant construction via friction-stir welding or brazing

Typical Architecture of a Diamond Thick Film Resistor Module

A commercial-grade Diamond Thick Film Resistor typically includes:

- Thick Film Resistor Chip: RuO₂ or Bi₂Ru₂O₇-based resistive paste, screen-printed on AlN or BeO, laser-trimmed to tolerance.

- CVD Diamond Insulator: 0.3–1.0 mm thick, metalized with Ti/Pt/Au for solderability.

- Copper PinFin Baseplate: Precision-machined with serpentine or straight coolant channels.

- High-Reliability Interconnects: AuSn or sintered silver bonding for low thermal resistance.

- Hermetic or Semi-Hermetic Enclosure: For protection in harsh environments.

Multiple resistor chips can be series/parallel-connected on a single diamond plate to achieve custom resistance values (e.g., 0.1 Ω to 100 Ω) and power ratings up to 50 kW.

Applications Driving Adoption

Diamond Thick Film Resistors are not for everyday circuits—they solve extreme engineering challenges:

- 48V Data Center Power Systems: Dynamic load banks for server PSU validation

- EV Battery Testing: Regenerative braking simulation and DC-link dump loads

- Rail & Aerospace: Braking resistors requiring high vibration tolerance and zero inductance

- Industrial Motor Drives: Snubber and braking circuits in high-power inverters

- Pulsed Power Systems: Radar, laser, and medical equipment requiring rapid heat removal

Their near-zero inductance design also makes them ideal for high-frequency switching environments where parasitic effects must be minimized.

Why Not Use Standard Ceramic Substrates?

Traditional Al₂O₃ or even AlN substrates struggle beyond 5–10 kW/cm². At higher power densities:

- Thermal runaway becomes likely

- Resistance drift accelerates

- Solder joints fatigue faster

Diamond substrates push this limit 3–5x higher, enabling smaller, lighter, and more reliable systems—critical in space-constrained applications like onboard EV chargers or modular data centers.

The Future: Cost vs. Performance Trade-Offs

Historically, CVD diamond was prohibitively expensive. But advances in polycrystalline diamond synthesis and localized diamond integration (e.g., diamond “islands” only under hot spots) are making these solutions more accessible.

For mission-critical, high-value systems, the total cost of ownership—including cooling infrastructure, footprint, and downtime—often justifies the upfront investment in diamond-based resistors.

Conclusion: Redefining Power Density Limits

Diamond Thick Film Resistors represent the convergence of advanced materials science, precision thick film technology, and innovative liquid cooling. By welding high-stability resistor elements onto diamond-insulated PinFin assemblies, engineers can now design ultra-compact, ultra-reliable load solutions for the most demanding power applications.

As data centers push toward 48V architectures and EVs demand faster, safer testing, this hybrid approach will only grow in importance.

Looking for a custom Diamond Thick Film Resistor solution? Contact our engineering team for PinFin-cooled, diamond-enhanced resistor modules rated from 10 kW to 50 kW, with options for dual-sided cooling, low inductance, and MIL-STD reliability.