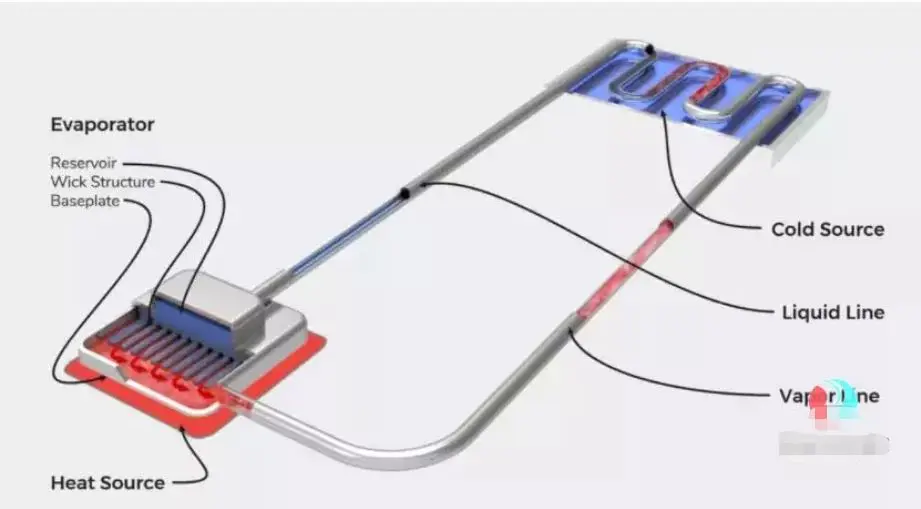

The application of the Loop Heat Pipe (LPP) principle in water-cooled resistors offers an innovative approach to managing the thermal challenges associated with high-performance electrical components. Designers can effectively harness the advantages of LHP technology in combination with water cooling to enhance the efficiency and reliability of resistors in various applications. Below are the key aspects and potential benefits of this integration.

Application of Loop Heat Pipe Principle in Water-Cooled Resistors

1. Enhanced Thermal Management: Efficient Heat Transfer: The LHP operates on the principle of capillary action and phase change to efficiently transfer heat away from the resistor. When combined with water cooling, the LHP can quickly transport heat from the resistor to the water-cooled heat exchanger, significantly improving thermal performance. -Localized Cooling: LHPs enable localized cooling directly at the resistor, which enhances the overall efficiency of the water-cooling system by minimizing heat buildup around the resistors.

2. Compact and Lightweight Design: Space Optimization: The integration of an LHP with a water-cooling system can reduce the overall footprint of thermal management solutions. LHPs can be designed to fit more compactly alongside resistors while their efficiency makes them suitable for smaller water-cooling systems. Modular Designs: The modular nature of LHPs allows for flexible configurations that are easier to integrate into existing systems or new designs without extensive modifications.

3. Improved Reliability and Lifespan: Lower Operating Temperatures: By efficiently transferring heat away from the resistor, LHPs help maintain lower operating temperatures. This reduced thermal stress leads to enhanced reliability and a longer lifespan for both the resistor and the cooling components. Reduced Thermal Cycling: Consistent and effective heat management minimizes thermal cycling, which can lead to material fatigue and failure in resistors.

4. Scalability and Adaptability: Variety of Power Levels: The LHP principle is easily scalable, allowing thermal management systems to be customized for resistors with varying power ratings. This scalability is critical in industries such as utilities, automotive, and renewable energy. Adaptable Cooling Solutions: As operational requirements change, the LHP and water-cooled system can adapt to different heat loads by altering fluid dynamics or adding/removing cooling circuits.

5. Energy Efficiency: Reduced Pumping Requirements: The use of LHPs can lower the required flow rates and energy consumption for water circulation, optimizing the overall energy efficiency of the thermal management system. Minimized Heat Loss: Effective heat transfer and management decrease the overall energy loss in the system, contributing to improved efficiency in applications such as power electronics and industrial machinery.

Example Application Case: Industrial Water-Cooled Resistor Bank

Overview: An industrial manufacturer is developing high-power resistor banks for dynamic braking systems in large electric motors. Managing the heat generated during operation is crucial to ensure reliable performance and longevity.

Implementation: LHP Integration: Each high-power resistor in the bank is coupled with a loop heat pipe system, which captures and conducts heat to a water-cooled heat exchanger. Water Cooling System: The heat exchanger circulates water, allowing for efficient heat removal and maintaining optimal operating temperatures for the resistors.

Performance Benefits: 1. Thermal Management: The combination of water cooling and LHP results in rapid heat dissipation from the resistors, allowing for continuous operation without overheating. 2. Compact Configuration: The system design efficiently uses space and minimizes the weight of the cooling assembly, making it ideal for installation in limited space. 3. Enhanced Efficiency: The system operates with lower energy consumption, providing significant operational cost savings for the manufacturer.

Conclusion The integration of the Loop Heat Pipe principle in water-cooled resistors presents a cutting-edge solution for managing heat in high-performance applications. This innovative approach not only facilitates effective thermal management but also enhances the reliability and efficiency of resistor systems across various industries, from industrial automation to automotive and aerospace applications. By leveraging the strengths of LHP technology, engineers can develop more robust and efficient thermal management systems tailored to meet the demands of modern electrical devices.